rondds

Well-Known Member

- Oct 3, 2006

- 8,859

- Boat Info

- 2001 380DA

- Engines

- Merc 8.1s (2008)...Hurth ZF 63 V-drives...WB 7.0 BCGD (2013), Garmin 8208 & 740 MFDs, GMR 24xHD dome

60 and sunny today. Great day for bilge diving.

Got the shaft back into position and through the stern tube. Inserted the red "hat" into the dripless and slipped it over the end of the shaft under the engine. At precisely that moment, my buddy Chris showed up to check on his boat. Instead I sent him under the boat to start pushing the shaft further in as I held the dripless in position.

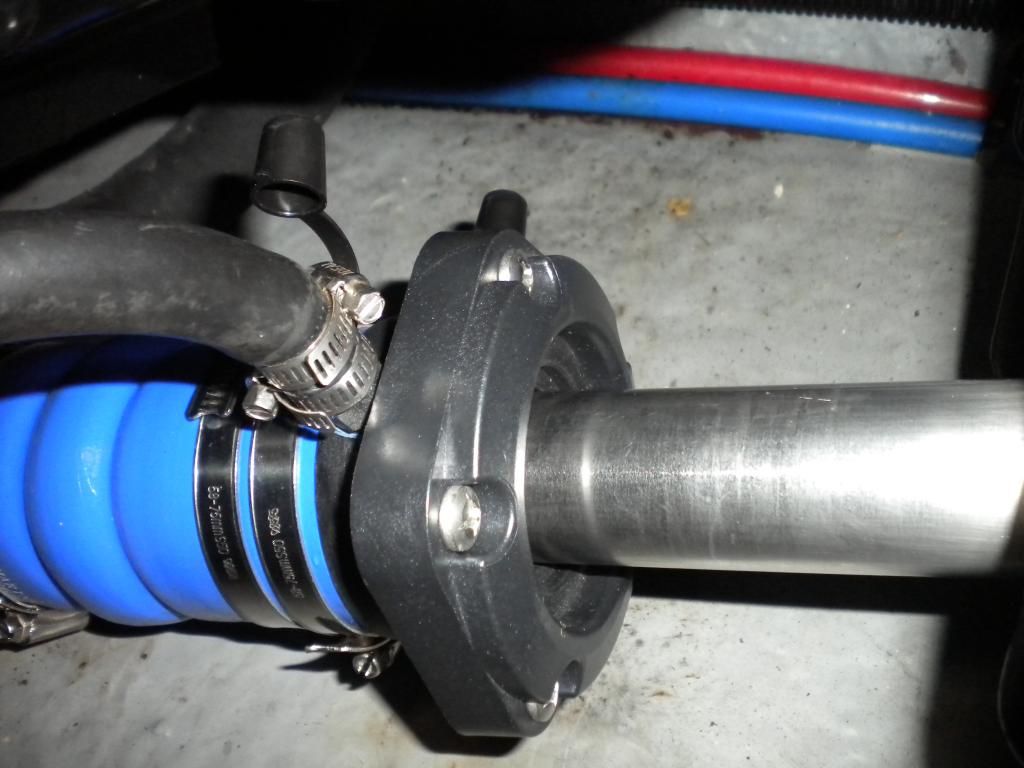

Here it is in position, hose clamps not tightened yet. The red hat protects the lip seal from damage as it slips over the keyway and threads. It also protects it from any nicks or dings in the shaft. I had the shaft at home and sanded it down step-wise to 600 grit paper, so there was not a nick or pit or anything to damage the lip seal.

Put the keyway and coupler back on with a little Mercury Extreme Grease, put the nut on the end with a schmear of anti-seeze, mated up the two coupler ends and tightened everything up. Removed the red hat thingy and it's done.

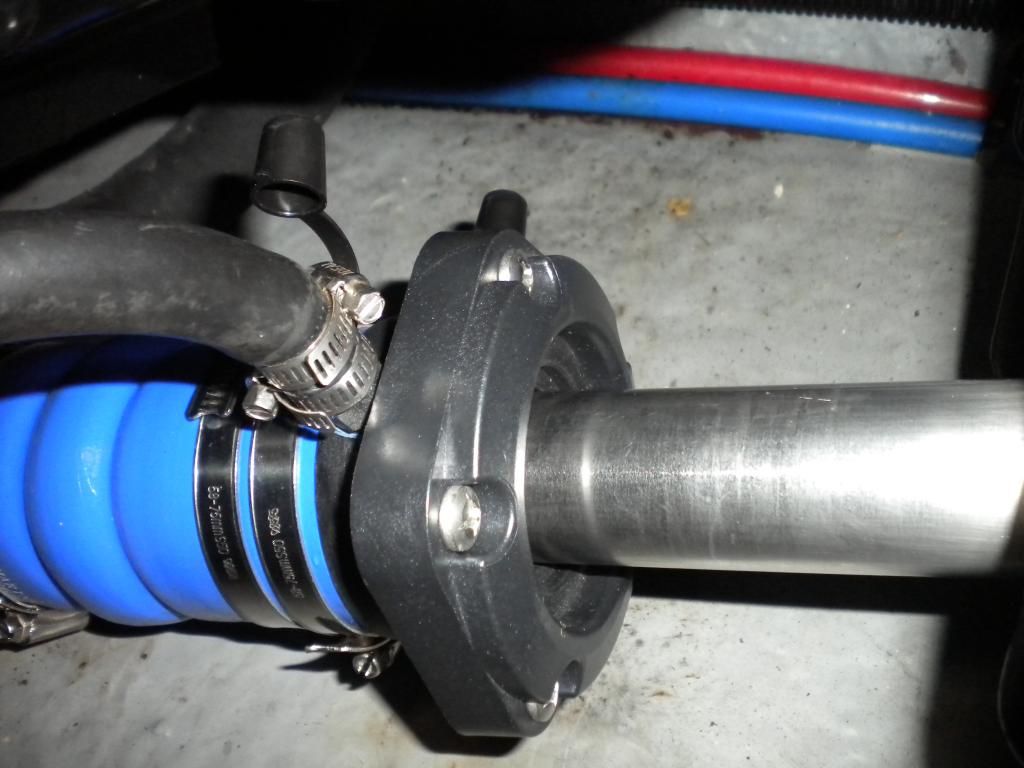

In the pic below you can see the other hose barb for the crossover. This boat did not have a crossover. I had spoken a couple of times to the tech people at Tides and they said that I can create a crossover on the dripless on the other engine (which only has one hose barb) but cutting the water feed and putting a "T" in. I was originally NOT going to do this - rather, I was going to remove the the 2nd hose barb (it's threaded in) and place a nylon plug. But I was guilted into it by someone. So now I need to order about 20' of 3/8" Type 1 fuel hose (that's what Tides recommends) and a brass T.

So this saga will continue.

Got the shaft back into position and through the stern tube. Inserted the red "hat" into the dripless and slipped it over the end of the shaft under the engine. At precisely that moment, my buddy Chris showed up to check on his boat. Instead I sent him under the boat to start pushing the shaft further in as I held the dripless in position.

Here it is in position, hose clamps not tightened yet. The red hat protects the lip seal from damage as it slips over the keyway and threads. It also protects it from any nicks or dings in the shaft. I had the shaft at home and sanded it down step-wise to 600 grit paper, so there was not a nick or pit or anything to damage the lip seal.

Put the keyway and coupler back on with a little Mercury Extreme Grease, put the nut on the end with a schmear of anti-seeze, mated up the two coupler ends and tightened everything up. Removed the red hat thingy and it's done.

In the pic below you can see the other hose barb for the crossover. This boat did not have a crossover. I had spoken a couple of times to the tech people at Tides and they said that I can create a crossover on the dripless on the other engine (which only has one hose barb) but cutting the water feed and putting a "T" in. I was originally NOT going to do this - rather, I was going to remove the the 2nd hose barb (it's threaded in) and place a nylon plug. But I was guilted into it by someone. So now I need to order about 20' of 3/8" Type 1 fuel hose (that's what Tides recommends) and a brass T.

So this saga will continue.