jmunro123

Member

My take.

Compound first-If not happy try the highest grit sandpaper-1000-1500 then compound again.

I've actually compounded out 400 grit scratches with a rotary buffer and my regular compound. I wouldn't do that on a flat surface though. This was small repair areas.

We have some areas that had heavy oxidation that actually gave the gelcoat a pitted appearance-base of the side windows. The first couple of years I basically shined up the pitted area but the texture remained. This area seemed to fade faster then the unharmed areas. Over the years and more compounding has eventually smoothed out the damaged ares and they hold up much better now. I do think severely chalked gelcoat will fade quicker UNLESS it is wet sanded or compounded out. Then it should revert back to normal durability if maintained. My thinking is to stay ahead of any chalking because once it starts it seems to snowball.

Carver: Your boat looks great! I give ya bridge guys credit as thats ALOT of gelcoat to take care of!

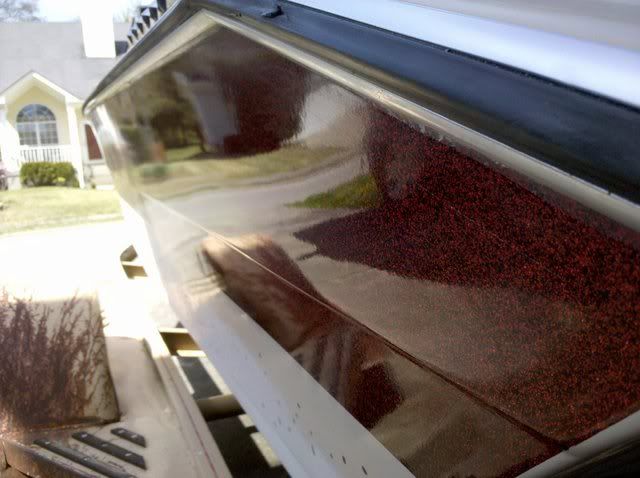

The pitting is actually what I think has happened to areas of my boat. Its only on the curved part of the cabin top and really only noticable on the radius. I have tried compound and it will shine after doing that but the small (and I do mean small ) pitting remains. I think I will step back to 1500 and just do the radius then Meguiar Oxidation remover then Buff Magic then polish and wax - but even then its 4 times over the surface + washing. Its a ton of work but the results will be worth it. After this mess I will be fine from here on in. Its just frusrating right now.

I can't wait to do the hull - that wil be simple Buff Magic and Polish maybe wax.