jmunro123

Member

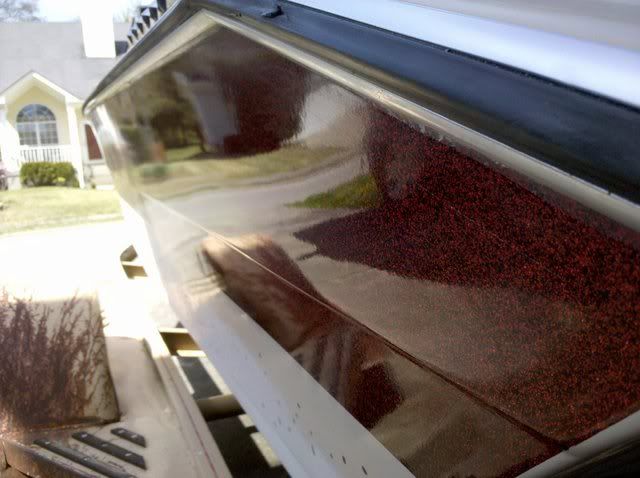

We purchased our 2004 390MY in June of 2010 and as I was trying to clean it , I noticed there were places that I could just not get to shine. I tried a number of different products including compound, buff magic and while the got it cleaner the fiberglass just did not shine. I was talking to a company that sells products and he mentioned trying some light wet sanding. Before trying this I used Buff Magic, Mequirs Oxiation restores and 3M heavy compound. All work to bring back a shine BUT - there were still very small marks - kind of like an imperfection in the fiberglass. I think the marks are from oxidation and those marks made it impossible to get that new boat deep shine.

I am relatively new to boat cleaning and really resist compound so you can imagine how I feel about wet sanding. Well today after lots of reading and Googling I decided to give it a try.

l was wondering what the effects are on fiberglass of wet sanding and if it increases the speed of oxidation? Is maintanance after this procedure more time consuming?

I would be interested in other CSR members who have done this can give me some insight into what to expect for future maintanance.

Just for reference this is the procedure that I did but it not really relevent to the question.

1. wet sand with 800 with sanding block - lightly and about 5 strokes back and forth

2. repeat wet sand with 1000 with sanding block - lightly and about 8 strokes back and forth

3 repeat wet sand with 2000 with sanding block - lightly and about 10 strokes back and forth

4. compound with Buff Magic with Shurhold polisher

5. finish with Pro Polish with Shurhold polisher

The net effect of using wet sanding in this particular case is it brought back the fiberglass to what looks like new condition. The results are actually amazing BUT the effort is significant. After completing the test areas I just sat down and pondered the effort to get this deck area done. Then went to the 'library' to sit at the bar and think of my next move.

I am relatively new to boat cleaning and really resist compound so you can imagine how I feel about wet sanding. Well today after lots of reading and Googling I decided to give it a try.

l was wondering what the effects are on fiberglass of wet sanding and if it increases the speed of oxidation? Is maintanance after this procedure more time consuming?

I would be interested in other CSR members who have done this can give me some insight into what to expect for future maintanance.

Just for reference this is the procedure that I did but it not really relevent to the question.

1. wet sand with 800 with sanding block - lightly and about 5 strokes back and forth

2. repeat wet sand with 1000 with sanding block - lightly and about 8 strokes back and forth

3 repeat wet sand with 2000 with sanding block - lightly and about 10 strokes back and forth

4. compound with Buff Magic with Shurhold polisher

5. finish with Pro Polish with Shurhold polisher

The net effect of using wet sanding in this particular case is it brought back the fiberglass to what looks like new condition. The results are actually amazing BUT the effort is significant. After completing the test areas I just sat down and pondered the effort to get this deck area done. Then went to the 'library' to sit at the bar and think of my next move.

Attachments

Last edited: