- Aug 25, 2008

- 1,819

- Boat Info

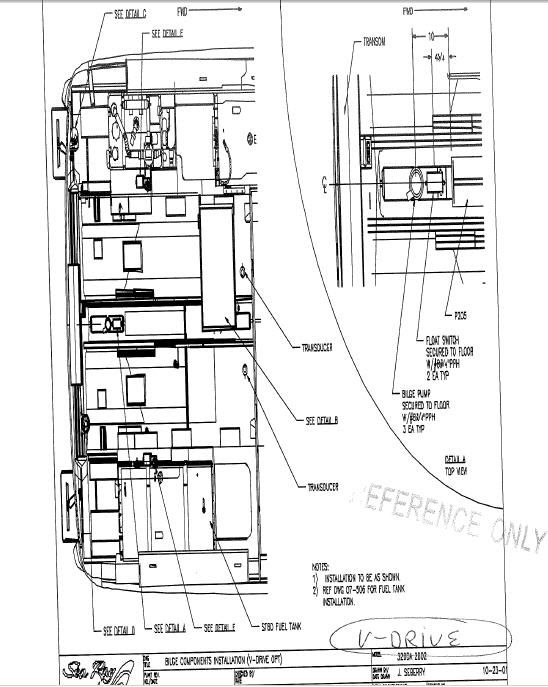

- 2006 320 V-Drives 6.2s, Bow Thruster, Generator, Raymarine C80, Radar, Fish Finder

- Engines

- 6.2 Horizons 320HP

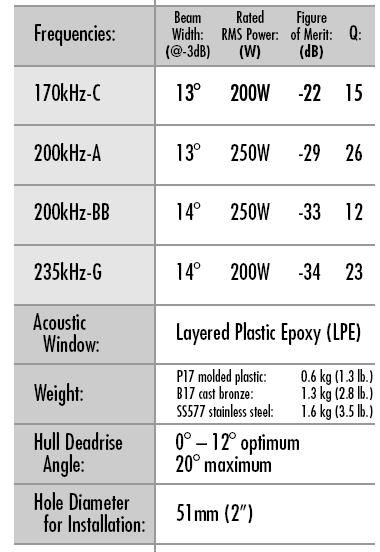

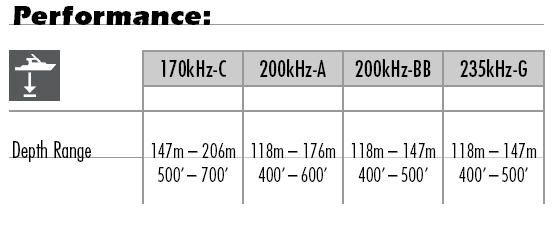

My big winter project was to add fish finding/sonar to my Raymarine C80 over the winter. I was able to get a great price on the transducer and DSM 30 at the NY boat show.

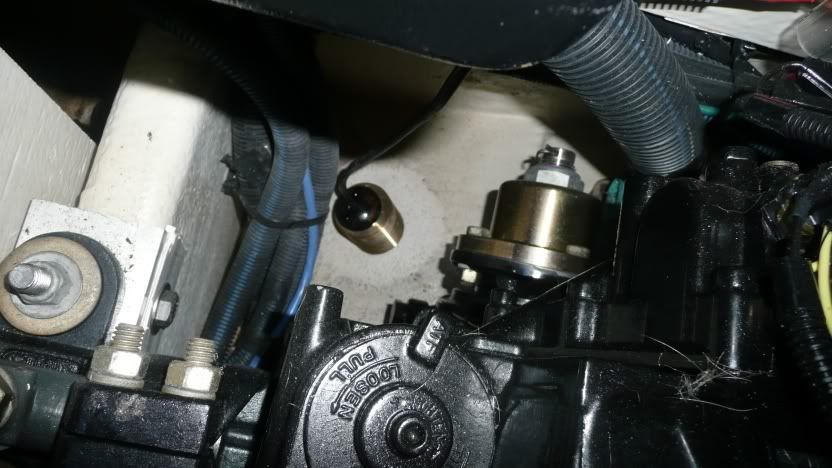

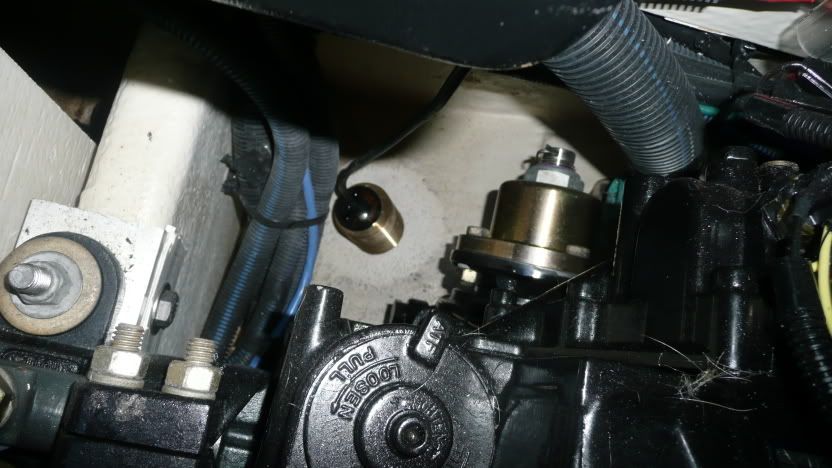

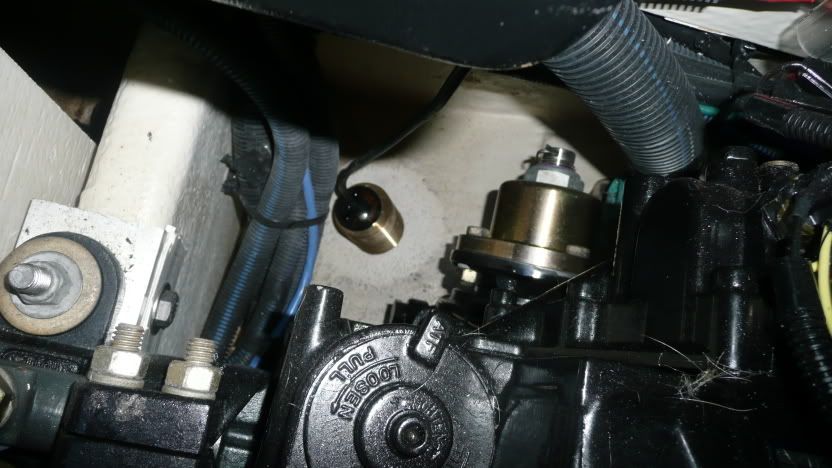

I installed the thru-hull transducer over the Christmas break. Technically the installation was pretty easy: Drill a hole using the correct size hole saw, sand and clean both the inside and outside of the hole, apply liberal amounts of 5200, install the transducer and gasket and tighten the nut. This is a picuture from the inside before the 5200, gasket and nut were installed.

The actual installation however was pretty difficult. It was a real bitch trying to tighten the nut while doing a head stand in the bilge. I was able to thread and tighten the nut by hand, but I had a had a very difficult time trying to get a channel lock on the nut to torque it down. Fortunately my friend with long arms was helping me and was able to reach the nut and tighten it for me. Everything looks good, but I cant call it a success until the boat goes back in the water and I confirm that there are no leaks and the unit is working.

I took a few pictures of the hole that I drilled and the core of fiberglass that I removed. I was a little surprised how thin the fiberglass was. Take a look:

I installed the thru-hull transducer over the Christmas break. Technically the installation was pretty easy: Drill a hole using the correct size hole saw, sand and clean both the inside and outside of the hole, apply liberal amounts of 5200, install the transducer and gasket and tighten the nut. This is a picuture from the inside before the 5200, gasket and nut were installed.

The actual installation however was pretty difficult. It was a real bitch trying to tighten the nut while doing a head stand in the bilge. I was able to thread and tighten the nut by hand, but I had a had a very difficult time trying to get a channel lock on the nut to torque it down. Fortunately my friend with long arms was helping me and was able to reach the nut and tighten it for me. Everything looks good, but I cant call it a success until the boat goes back in the water and I confirm that there are no leaks and the unit is working.

I took a few pictures of the hole that I drilled and the core of fiberglass that I removed. I was a little surprised how thin the fiberglass was. Take a look: