ks65609

Member

- Aug 30, 2009

- 342

- Boat Info

- 1992 330 Sundancer

- Engines

- Twin 454 Mercruiser--340hp

V drive inboards

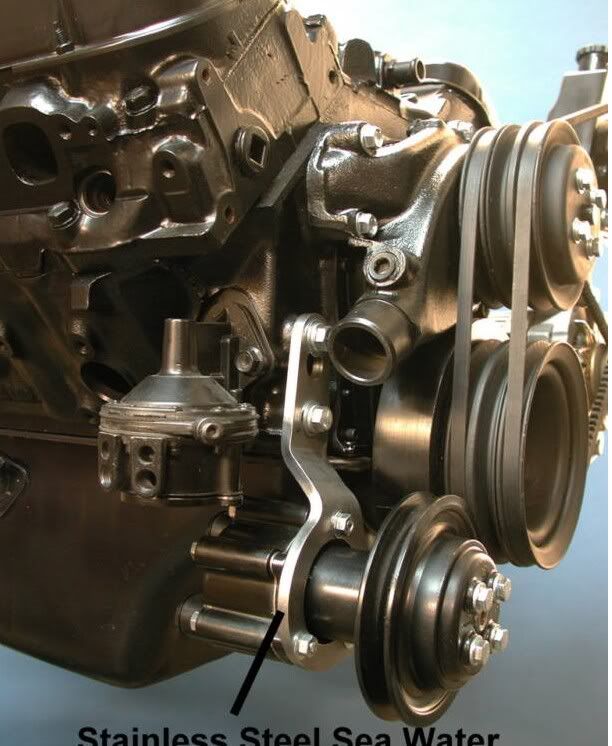

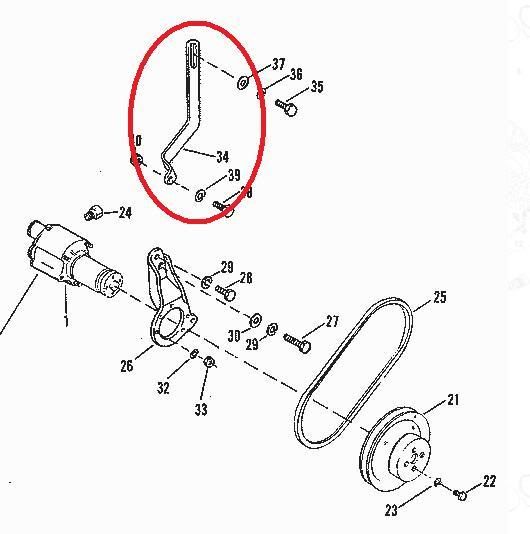

I would like to request information regarding replacing raw water impellers on our 89 300 Weekender with 454 direct drive inboards

It looks to me that the entire belt driven pump should be removed in order to replace the impeller, however before I start tearing things apart I am hoping someone may be able to give me some good advice. It look like removing two of the three batteries would create enough space to access the port engine however have not looked at the starboard as of yet.

If anyone has tackled this project I would sure appreciate your input.

Thanks

Ken

It looks to me that the entire belt driven pump should be removed in order to replace the impeller, however before I start tearing things apart I am hoping someone may be able to give me some good advice. It look like removing two of the three batteries would create enough space to access the port engine however have not looked at the starboard as of yet.

If anyone has tackled this project I would sure appreciate your input.

Thanks

Ken