JByers

New Member

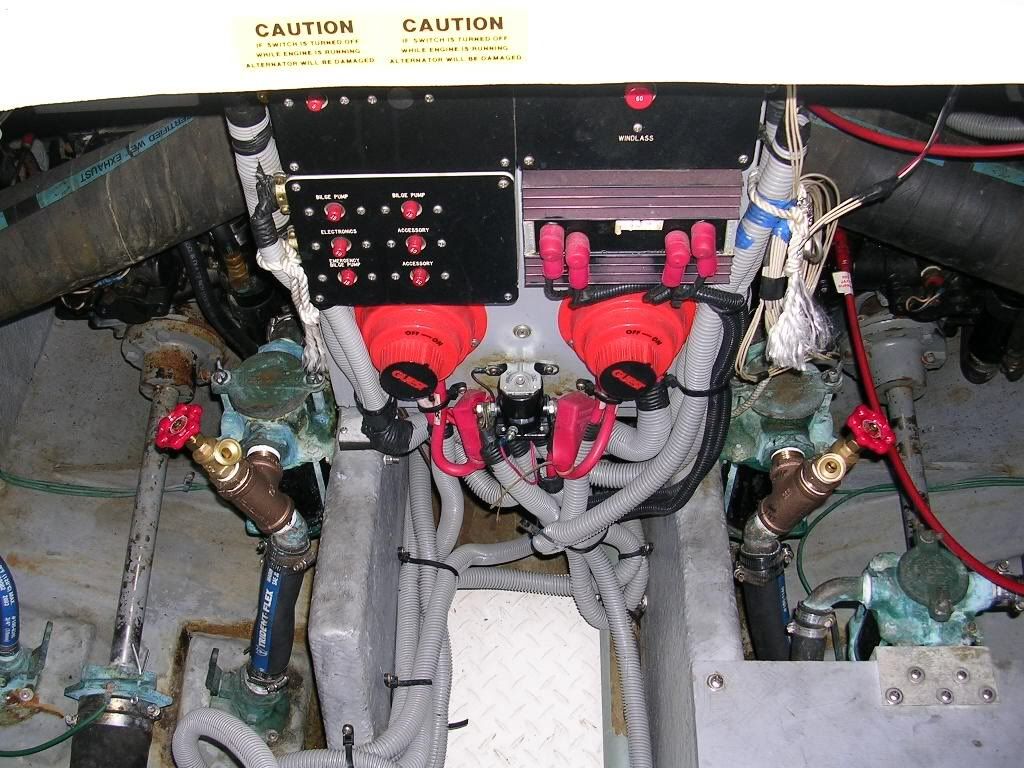

I have to winterize my own boat engines this fall. The SeaRay manual says see Merc manual, which I don't have. The boat is a 2001 34' with Merc 6.2 engines.

Does anyone have a manual they want to sell?

Does anyone know how to winterize the oil coolers on the bottom of the engines?

Any help would be greatly appreciated. Thanks John :smt100

Does anyone have a manual they want to sell?

Does anyone know how to winterize the oil coolers on the bottom of the engines?

Any help would be greatly appreciated. Thanks John :smt100

Last edited: