osd9

New Member

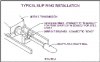

I just got a call from the marina and they wanted to know if I wanted them to install shaft zincs on my boat. On the last 3 inboard boats that I have owned, I have always put shaft zincs on. Except for the first time (after learned the proper way to set a shaft zinc) I have never had a problem with them coming loose or causing damage. The service manager said that Sea Ray no longer installs shaft zincs. He said that Sea Ray told the resellers that the zincs had a tendency to come loose, slide down the shaft and cause damage.

I asked the service manager if I don't put zincs on the shafts, what would protect my props and shafts. He said that they are bonded through the engine to the hull zinc.

I gave him the OK to NOT install shaft zincs......

What do other guys do.......? Oh...and do you paint your shafts...?????... :huh:

I asked the service manager if I don't put zincs on the shafts, what would protect my props and shafts. He said that they are bonded through the engine to the hull zinc.

I gave him the OK to NOT install shaft zincs......

What do other guys do.......? Oh...and do you paint your shafts...?????... :huh: