Ramblin' Guy

Active Member

- Nov 8, 2021

- 156

- Boat Info

- 1997 370 Sundancer

- Engines

- 370 hp 7.4 MPI Horizon w/V drives

Quick question for the hive mind tonight...

I have a 370 DA that I'd like to install a Raymarine CPT-120 thru hull transducer in for my new Axiom 7 DV. I have an existing install of a ST60 Tridata Depth/Speed that I'm thinking about keeping because the transducers are in the boat already and it's always nice to have a dedicated depth/speed gage in big print for older mariners.

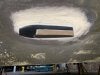

I'm thinking about installing the CPT-120 between the existing transducers for the depth/speed behind the bilge pump in the attached picture. My questions are, is this location OK (too close, on keel, whatever), and is it okay to run both of these things at the same time interference-wise? I think the frequencies are different, but not sure what they are. I'm aware that I need STNG to ST1 convertors - that's no problem.

Just wondering if anyone else has done this and has any advice before I drill the big hole in the bottom of the boat.

Any advice on the subject is always appreciated.

I have a 370 DA that I'd like to install a Raymarine CPT-120 thru hull transducer in for my new Axiom 7 DV. I have an existing install of a ST60 Tridata Depth/Speed that I'm thinking about keeping because the transducers are in the boat already and it's always nice to have a dedicated depth/speed gage in big print for older mariners.

I'm thinking about installing the CPT-120 between the existing transducers for the depth/speed behind the bilge pump in the attached picture. My questions are, is this location OK (too close, on keel, whatever), and is it okay to run both of these things at the same time interference-wise? I think the frequencies are different, but not sure what they are. I'm aware that I need STNG to ST1 convertors - that's no problem.

Just wondering if anyone else has done this and has any advice before I drill the big hole in the bottom of the boat.

Any advice on the subject is always appreciated.