melida

Member

- Apr 1, 2009

- 897

- Boat Info

- Sea Ray 2007 375 DA

Sea Ray 2005 315 DA Sold

- Engines

- 2xYANMAR 6LPA-STP 315 HP V-drives, 4kw Onan gen, radar, gps, autopilot, bow&stern thrusters, sat tv

Hi to all current and past 2003,5-2008 340DA owners..

I’m planning to buy a diesel 340DA (which is the smallest V-drive diesel) if I can sell my 2005 280DA, and narrowed my search to a loaded 2007 340 which fits to my boating style and pocket, but have some questions and concerns about design/accommodation, hope you can answer and convince me.

First of all being a 2005 280DA owner wife and 8 year old daughter doesn’t like the cockpit seating plan of the 340. The helm seats are fixed and they have bucket style side supports where same era 320DA’s helm seats are flat and you can lie your feet while anchored, so useless space for the 340.

How many people comfortably seat to the J shaped aft cockpit seating while cruising and anchored ?

Is it possible to convert the port side companion seat to a swivel seat like the 2008+ newer 340DAs?

The aft locker raises with the engine hatch so it is not fixed and the gap between the starboard aft corner of locker and hull seems to allow rain and hose water into the engine room or am I wrong?

I saw that battery charger/converter is reached from the mid cabin port locker to view the charge condition but how easy to replace it when it dies?

The owners/parts manuals shows that there is void space in front of the port batteries, is it really empty or the battery charger lays there?

The generator in the boat (is placed at the starboard aft corner) that I want to buy has a sound box and really quitens the genny and it was difficult to hear the starting noise. But when the raw water pump impeller will be changed the starboard hatch lift motor must be uninstalled according to owner due to the sound box? Is it true? if so how easy to do it and how to secure the entire cockpit with port hatch lift motor?

There is a synchronizer gauge at the helm but it isn’t electronic, so how reliable is it or is it worth add electronic?

The fresh water tank is under the mid cabin, so how easy to reach/take out in case of leak/crack?

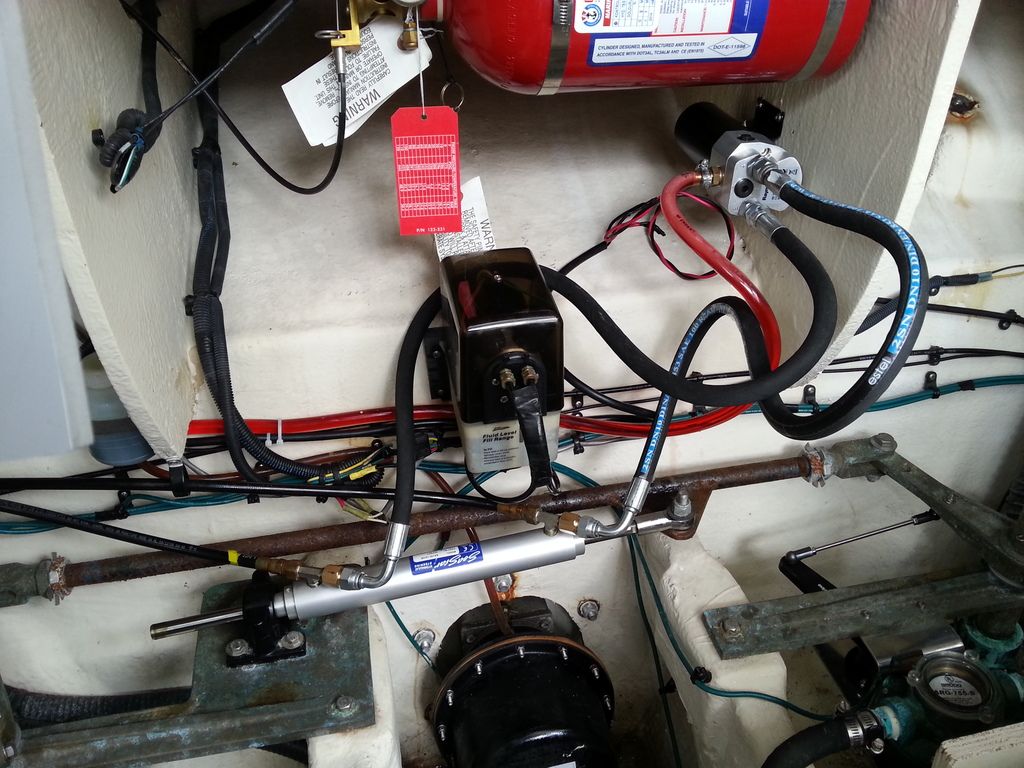

This particular boat have lots of options and only missing is autopilot to me, so I’ll add it when the time comes. Where are the fluxgate compass and core pack placed when the boat ordered new from Searay?

I saw in the manuals that there is a huge locker under the salon sofa,but no lids like in the 320DA and there is a cover/cap in my future boat when I pulled the sofa for converting to bed and the owner said there isn’t a locker under the sofa. Isn’t it strange?

Up to now these are my and my families concerns about the 340, and I don’t want them to be unhappy if I buy the 340.

I know you’ll tell that go buy 2004ish 360DA or go a few years older and buy a 2001ish 380DA but they don’t fit to my boating style/anchorages etc and huge increase in the annual operating costs which I barely convinced the admiral for the 340.

Greatly appreciated for your comments and answers in advance.

I’m planning to buy a diesel 340DA (which is the smallest V-drive diesel) if I can sell my 2005 280DA, and narrowed my search to a loaded 2007 340 which fits to my boating style and pocket, but have some questions and concerns about design/accommodation, hope you can answer and convince me.

First of all being a 2005 280DA owner wife and 8 year old daughter doesn’t like the cockpit seating plan of the 340. The helm seats are fixed and they have bucket style side supports where same era 320DA’s helm seats are flat and you can lie your feet while anchored, so useless space for the 340.

How many people comfortably seat to the J shaped aft cockpit seating while cruising and anchored ?

Is it possible to convert the port side companion seat to a swivel seat like the 2008+ newer 340DAs?

The aft locker raises with the engine hatch so it is not fixed and the gap between the starboard aft corner of locker and hull seems to allow rain and hose water into the engine room or am I wrong?

I saw that battery charger/converter is reached from the mid cabin port locker to view the charge condition but how easy to replace it when it dies?

The owners/parts manuals shows that there is void space in front of the port batteries, is it really empty or the battery charger lays there?

The generator in the boat (is placed at the starboard aft corner) that I want to buy has a sound box and really quitens the genny and it was difficult to hear the starting noise. But when the raw water pump impeller will be changed the starboard hatch lift motor must be uninstalled according to owner due to the sound box? Is it true? if so how easy to do it and how to secure the entire cockpit with port hatch lift motor?

There is a synchronizer gauge at the helm but it isn’t electronic, so how reliable is it or is it worth add electronic?

The fresh water tank is under the mid cabin, so how easy to reach/take out in case of leak/crack?

This particular boat have lots of options and only missing is autopilot to me, so I’ll add it when the time comes. Where are the fluxgate compass and core pack placed when the boat ordered new from Searay?

I saw in the manuals that there is a huge locker under the salon sofa,but no lids like in the 320DA and there is a cover/cap in my future boat when I pulled the sofa for converting to bed and the owner said there isn’t a locker under the sofa. Isn’t it strange?

Up to now these are my and my families concerns about the 340, and I don’t want them to be unhappy if I buy the 340.

I know you’ll tell that go buy 2004ish 360DA or go a few years older and buy a 2001ish 380DA but they don’t fit to my boating style/anchorages etc and huge increase in the annual operating costs which I barely convinced the admiral for the 340.

Greatly appreciated for your comments and answers in advance.