- Oct 4, 2006

- 2,335

- Boat Info

- 2003 280DA and 1995 Sea Ray 175

- Engines

- Twin 4.3l and 3.0l, all w/ AlphaI GenII drives

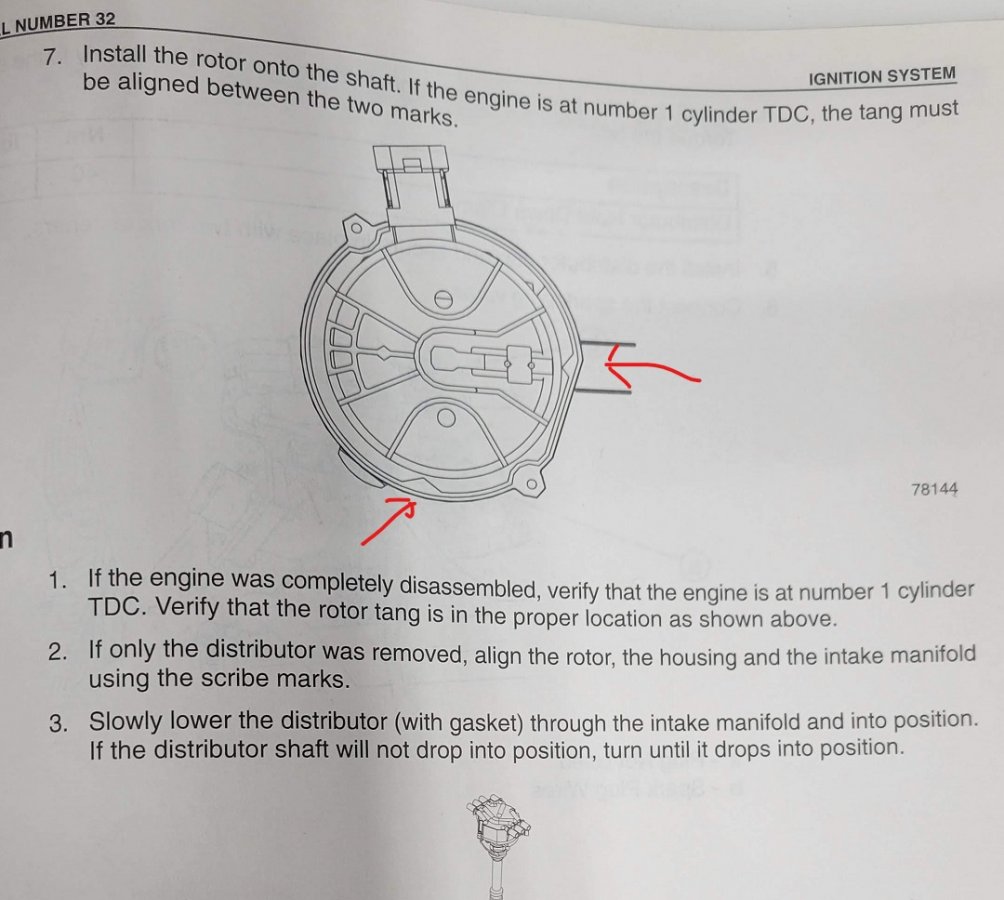

I'm to the point of installing the distributor in my brand-new 4.3 MPI engine. I have the engine at TDC on the #1 cylinder, ready for it to be installed. According to the manual (specifically for 4.3MPI), shown below, I aligned the tang of the rotor between the two marks. Between these two marks on the distributor is a little arrow casting, with the number "8" printed on it. So I put the rotor in this position on the bench, aligned the oil pump shaft properly to engage the bottom of the distributor and then installed it.

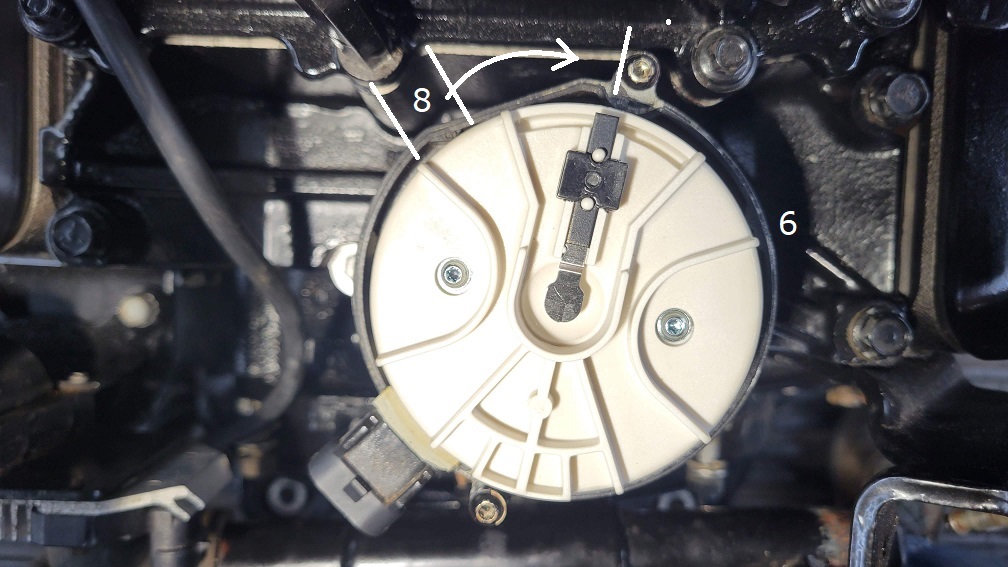

As the distributor engaged the camshaft, the rotor rotated clockwise, away from this position. It then engaged the oil pump shaft and seated down on the intake manifold, ready to bolt down. This is a photo if it installed. You can see where the rotor rotated to in its finally resting position:

My question is to anyone who has done this before...is this correct?! According to the manual, I think it is. Or, should the rotor tang be within those two marks *after* full installation? Because I can read #7 two ways...(1) That it's telling me to do that before Step #1 in the installation below it, or (2) as a note that after installation, if the engine is at #1 TDC, the rotor should align between those two marks. I can go both ways in my head!

Or...and now here is where things get interesting. When I went searching for an answer, I found a Youtube video where someone was installing this same distributor in a 4.3 Vortec in a Chevy truck. In the video, he pointed out those "8" and "6" numbers cast into the housing, at these two little arrow pointer things also cast in the housing. If you look at the manual photo you can see where I marked with red arrows these two pointers. The manual makes no mention of these or the numbers within them. The person in the Youtube video said to align the rotor tang with the "6" for a 6 cylinder engine.

But then the Youtube video went on to say that there may be little scribe marks on the tail end of the distributor that give you an offset to position the rotor tang, so when it engages the camshaft and rotates, it ends up where you want it pointing at the 6. Which made me also wonder...should the pointer -end up- when fully seated pointing at the "6" for a 6-cylinder?

So I'm left with a couple of questions and a lot of anxiety now. Is it just plain different for Mercruiser versus GM due to the ignition software? I really want to be confident this thing will fire up when I install it in the boat! I also know it will be very difficult to remove and reposition this distributor with the engine in the boat (near impossible?!). If anyone has done with before, or can offer any help, please let me know!

Thanks,

Tom

As the distributor engaged the camshaft, the rotor rotated clockwise, away from this position. It then engaged the oil pump shaft and seated down on the intake manifold, ready to bolt down. This is a photo if it installed. You can see where the rotor rotated to in its finally resting position:

My question is to anyone who has done this before...is this correct?! According to the manual, I think it is. Or, should the rotor tang be within those two marks *after* full installation? Because I can read #7 two ways...(1) That it's telling me to do that before Step #1 in the installation below it, or (2) as a note that after installation, if the engine is at #1 TDC, the rotor should align between those two marks. I can go both ways in my head!

Or...and now here is where things get interesting. When I went searching for an answer, I found a Youtube video where someone was installing this same distributor in a 4.3 Vortec in a Chevy truck. In the video, he pointed out those "8" and "6" numbers cast into the housing, at these two little arrow pointer things also cast in the housing. If you look at the manual photo you can see where I marked with red arrows these two pointers. The manual makes no mention of these or the numbers within them. The person in the Youtube video said to align the rotor tang with the "6" for a 6 cylinder engine.

But then the Youtube video went on to say that there may be little scribe marks on the tail end of the distributor that give you an offset to position the rotor tang, so when it engages the camshaft and rotates, it ends up where you want it pointing at the 6. Which made me also wonder...should the pointer -end up- when fully seated pointing at the "6" for a 6-cylinder?

So I'm left with a couple of questions and a lot of anxiety now. Is it just plain different for Mercruiser versus GM due to the ignition software? I really want to be confident this thing will fire up when I install it in the boat! I also know it will be very difficult to remove and reposition this distributor with the engine in the boat (near impossible?!). If anyone has done with before, or can offer any help, please let me know!

Thanks,

Tom

Last edited: