- Oct 4, 2006

- 2,335

- Boat Info

- 2003 280DA and 1995 Sea Ray 175

- Engines

- Twin 4.3l and 3.0l, all w/ AlphaI GenII drives

Hello all, I'm having an issue where my starboard trim won't go down at switch but will go down at solenoid when jumped to test according to the Mercruiser manual. So unfortunately the solenoid is good, which means it's either a wiring issue, or more likely an issue with the button on the dual throttle control.

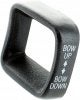

I wasn't able to figure out what model number of Mercury throttle control this is, but it's the stock OEM one on this 2003 280DA.

Has anyone disassembled this thing before and know the wiring schematic? I took off the cover and found a small set of wires, but not sure how they get up the shaft to the handle and switches. I could test them right here and see if I can get the starboard trim down to operate, if I knew which wires to probe or jump...

I also have an issue where the side mounted push button that engages throttle-only control seems to be stuck for the port side. It won't push in. The starboard side works fine. Any ideas on that?

Or maybe it's just time for a new throttle control. Has anyone replaced theirs?!

Thanks,

Tom

I wasn't able to figure out what model number of Mercury throttle control this is, but it's the stock OEM one on this 2003 280DA.

Has anyone disassembled this thing before and know the wiring schematic? I took off the cover and found a small set of wires, but not sure how they get up the shaft to the handle and switches. I could test them right here and see if I can get the starboard trim down to operate, if I knew which wires to probe or jump...

I also have an issue where the side mounted push button that engages throttle-only control seems to be stuck for the port side. It won't push in. The starboard side works fine. Any ideas on that?

Or maybe it's just time for a new throttle control. Has anyone replaced theirs?!

Thanks,

Tom

Last edited: