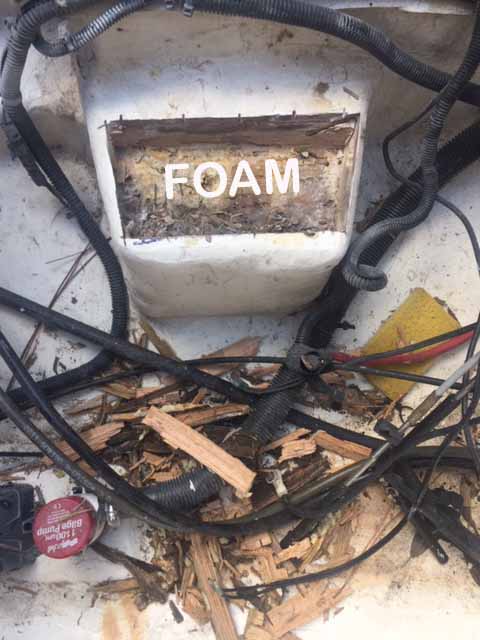

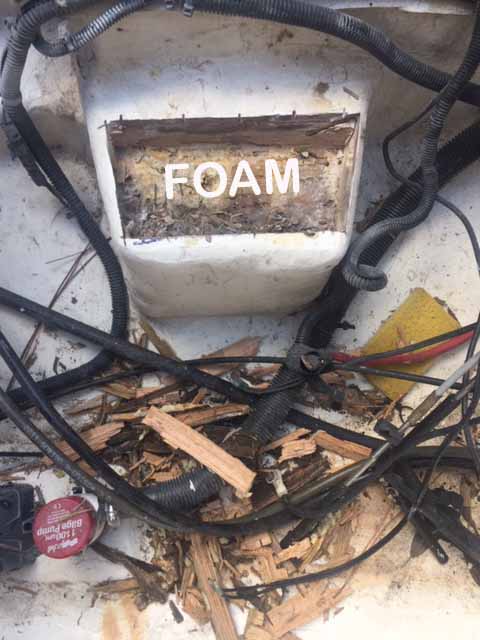

I'm repowering my 2006 185 after a bad 3.0 and I noticed when I removed the lag bolts from the forward engine mounts it appeared to be wet wood coming out. Does anyone know what is inside the engine mount blocks in the hull (see picture), the engine is out so if I'm going to do a repair now is the time. Anybody ever peeled the top fiberglass off the blocks? Any advice/information is greatly appreciated

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature currently requires accessing the site using the built-in Safari browser.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Engine Mount Block Construction

- Thread starter Ammo Dawg

- Start date

scoflaw

Well-Known Member

- Aug 10, 2011

- 6,395

- Boat Info

- 1999 Powerquest legend 260 sx 502 mag

2005 Baja 242 islander 496

- Engines

- 502 mpi Bravo 1

496 mag B1

Cut the top off, glass in another chunk of wood or fill with glass and fiber

Thanks! How many layers of glass would you put on top? Also any recommendation on wood to use, again thanks.Cut the top off, glass in another chunk of wood or fill with glass and fiber

- Jun 5, 2016

- 5,592

- Boat Info

- 410 Sundancer

2001

12" Axiom and 9" Axiom+ MFD

- Engines

- Cat 3126 V-Drives

Its exactly that...wet rotted wood. Has to be rebuilt. I am no fiberglass guru, but I enjoy watching boatworkstoday.com on Youtube. Professional fiberglass guy that has little videos on how to fix fiberglass and gelcoat. He has an online guide for choosing the right fiberglass products. Between that and the videos, I bet you could learn enough to do a professional job.

Bt Doctur

Well-Known Member

Cut the top skin off and check the damage.Keep cutting back until for get to dry wood.

Oak.Poplar ,etc cut to size and glassed into place

Oak.Poplar ,etc cut to size and glassed into place

I have tried to verify that with no luck, even contacted Sea Ray and they sent me to a local shop who really didn’t know. Was hoping Simone had peaked back the top of one of those mounts, now is the time to do the repair if it is needed.Wait, I thought since 2001? all seaways were 100% fiberglass. no wood. You probably just found sealant they used when installing the fasteners. I would confirm if boat even has wood.....

I have tried to verify that with no luck, even contacted Sea Ray and they sent me to a local shop who really didn’t know. Was hoping Simone had peaked back the top of one of those mounts, now is the time to do the repair if it is needed.

douglee25

Well-Known Member

Stick your screwdriver down the lag hole and try to pry some material out. If it's truly wet wood, it will come out with ease.

scoflaw

Well-Known Member

- Aug 10, 2011

- 6,395

- Boat Info

- 1999 Powerquest legend 260 sx 502 mag

2005 Baja 242 islander 496

- Engines

- 502 mpi Bravo 1

496 mag B1

Regardless, you need to cut the top off and repair it.

Arminius

Well-Known Member

- Oct 30, 2019

- 1,068

- Boat Info

- Bowrider 200 Select, 2003

- Engines

- 5.0L MPI, 260 hp w/Alpha 1 Drive

This is a job for an expert, I'm not. The starboard mount would be critical as your prop is turning clockwise, tending to lift that side every time you accelerate. Super glued layer cake seems unlikely to fix it as a lag would just pull it apart or out. I'd think about demo=ing down to the underlying stringer. Maybe you could chain that corner of the engine down to sound structure for the remaining life of the boat.

Gotta cure the water intrusion. Better to always pull the bilge plug on a trailer boat and wire it to the receiver latch.

Gotta cure the water intrusion. Better to always pull the bilge plug on a trailer boat and wire it to the receiver latch.

Last edited:

I don't know if rotted or not. At most i would dig out the soft stuff if any. If the holes becomes to big but you know you have good material left fill hole with marine tex. let dry. Drill and screw lag bolt back in. Your done. I did a similar repair 15 years ago. To this date the bolts are still tight and alignment has never moved. Remember you have two mounts on the back of the boat so in reality you have 4 mounts.

Your motor mounts are not even rusted. They look new. I think you dug out sealant.

Your motor mounts are not even rusted. They look new. I think you dug out sealant.

- Sep 25, 2016

- 1,257

- Boat Info

- 300 Sundancer 1994, trailered tri-axle LoadRite roller

- Engines

- Mercruiser 5.7 260HP Alpha One Gen II, twin

First when people talk of a 100% fiberglass hull they mean the bottom is solid fiberglass and not balsa cored.

Every Sea Ray has plywood core in the transom. Plywood stringers and frames and bulkheads.

If water is allowed to leak and stand for years water will get into the stringers.

Even the stringers are only fully glassed over in the engine area. Under flooring and forward areas it is usually only glassed up from the hull 6 to 10”.

I have a 1994 300 and had to do major stringer work.

So yes now is the time to check this while you have the engine out. Maybe just the mount block, maybe more. Better to be sure.

Start small, drill a 3/8” hole in the side go in at least an inch. See what the wood feels like. Squeeze it is it wet?

Poke in the hole it should be solid.

If the wood is good just fill the hole with epoxy.

But if not cut open the box and keep digging till you find hard dry wood.

Every Sea Ray has plywood core in the transom. Plywood stringers and frames and bulkheads.

If water is allowed to leak and stand for years water will get into the stringers.

Even the stringers are only fully glassed over in the engine area. Under flooring and forward areas it is usually only glassed up from the hull 6 to 10”.

I have a 1994 300 and had to do major stringer work.

So yes now is the time to check this while you have the engine out. Maybe just the mount block, maybe more. Better to be sure.

Start small, drill a 3/8” hole in the side go in at least an inch. See what the wood feels like. Squeeze it is it wet?

Poke in the hole it should be solid.

If the wood is good just fill the hole with epoxy.

But if not cut open the box and keep digging till you find hard dry wood.

This is only partially correct. A lot of things have changed in a quarter century. Starting in the mid-'90's the sport boats started using a fiberglass hull liner - this started with the 175BR and progressed to other models.. This meant, while there was/is still plywood in the transom, the entire hull, floor and stringer system is all fiberglass/composite. I'm not 100% positive, but I believe there is still wood used for the motor mount area for the lag screws.First when people talk of a 100% fiberglass hull they mean the bottom is solid fiberglass and not balsa cored.

Every Sea Ray has plywood core in the transom. Plywood stringers and frames and bulkheads.

If water is allowed to leak and stand for years water will get into the stringers.

Even the stringers are only fully glassed over in the engine area. Under flooring and forward areas it is usually only glassed up from the hull 6 to 10”.

I have a 1994 300 and had to do major stringer work.

.

Espos4

Well-Known Member

This is a job for an expert, I'm not. The starboard mount would be critical as your prop is turning clockwise, tending to lift that side every time you accelerate. .

Actually it’s the opposite. The port side mount is being pulled up and the starboard side mount is being pushed down by the torque of the rotating engine.

When looking at the front of the motor, the crank pulley rotates clockwise.

Power brake any longitudinal automotive engine and watch the engine tilt toward the passenger side, or ask any Hot Rodder which motor mount breaks first, it’s the driver side.

Arminius

Well-Known Member

- Oct 30, 2019

- 1,068

- Boat Info

- Bowrider 200 Select, 2003

- Engines

- 5.0L MPI, 260 hp w/Alpha 1 Drive

Here's the diary of a major motor mount + repair:

http://www.clubsearay.com/index.php?threads/stringer-motor-mount-repair.92239/

http://www.clubsearay.com/index.php?threads/stringer-motor-mount-repair.92239/

My boat has a lifetime haul and transom warranty. Does yours? mine is a 2011.

a limited lifetime hull and deck warranty, integral armrests, beverage holders, soft sided carry-on cooler, soft touch dashboard, fiberglass stringers

I would starting cutting and destroying anything. Understand what YOUR boat has not what others think feel it has...

a limited lifetime hull and deck warranty, integral armrests, beverage holders, soft sided carry-on cooler, soft touch dashboard, fiberglass stringers

I would starting cutting and destroying anything. Understand what YOUR boat has not what others think feel it has...

Last edited:

Steve in Minneapolis

Active Member

- Jul 20, 2020

- 248

- Boat Info

- 2021 290 SDX

350 HP Mercruiser

Metallic blue with Sand (bar) interior

- Engines

- 350 Mercruiser with Bravo III

Good point with the hull warranty. However, that cannot be transferred. It's only for the original owner. Not sure about OP...

For grins i tightened my motor mount bolts today. They weren't tight to begin with, i got a 1/5 turn pretty easy. once snug i didn't go ape on them. learning is if they snug up pretty good your good. i probably have 20 ft-lbs on mine. the front ones on the side. if they torque tight and don't keep twisting your good. my boat alignment has been perfect for over 3 years now.

Well I had to find out before I put the engine back in if I had rot in the forward engine mounts and see how they were constructed. As I suspected there was some wood in there after I removed the top and the starboard mount had rot only around the bolt holes were as the port one was in much worse shape. Basically, there is a piece of 1 1/2" wood inside the mount tower. I was surprised to see that the wood doesn't tie into any other structure, it sits on foam, and has foam surrounding it on all four sides. I cut down some 2 x 6 lumber, non pressure treated, foam was dry so I left that intact. I glassed it in with six layers of 1780, the piece I cut out was about 3/16" to 1/4" thick, like to hear your thoughts, I can add more. Again, this is a 2006 Sea ray 185 Sport and I'm putting in a 4.3 to replace the 3.0 I had in it.