I have easy access to these pumps on both my engines (forward facing engines with straight shafts). There is also plenty of room to sit directly in front of the engines.

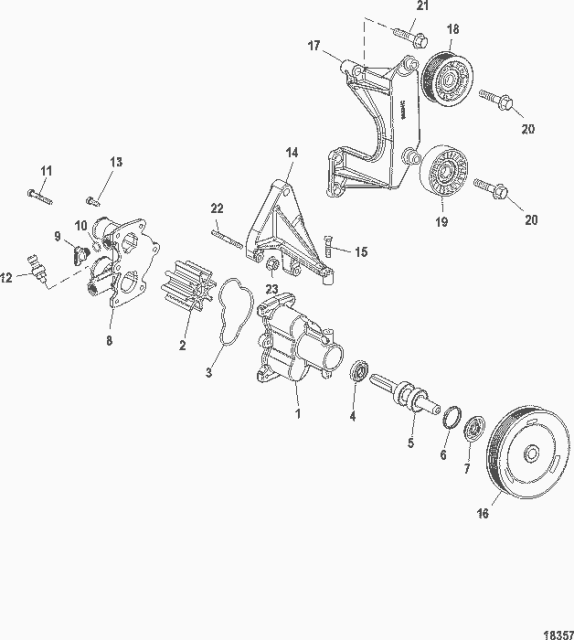

Is it necessary to remove the entire unit, hoses and all - or is it possible to just remove the front housing (from the pulley to the rear part of the casing) and expose the impellar for replacement? :huh:

I haven't taken a real close look at it but I remember seeing 3 or 4 bolts that seem to hold the two halves of the pump together. From this report it sure sounds like taking the hoses off is the most labour, so if it can be avoided that would be great! :thumbsup:

I might be possible to not have to remove them on your boat but, the problem is that the bolt that hold the two halves of the pump together are on the back side. With the hoses in place, it may be a major PITA to R&R the bolts.

As far as priming the pumps, all I used was a bunch of dish soap. I put some between each vane before bolting the pump body back together and another shot down the outlet port before installing.

I will do the stbd side again when its needed but I'm paying for the port side, I'm about 6'7" and it's just not worth it...