mobocracy

Active Member

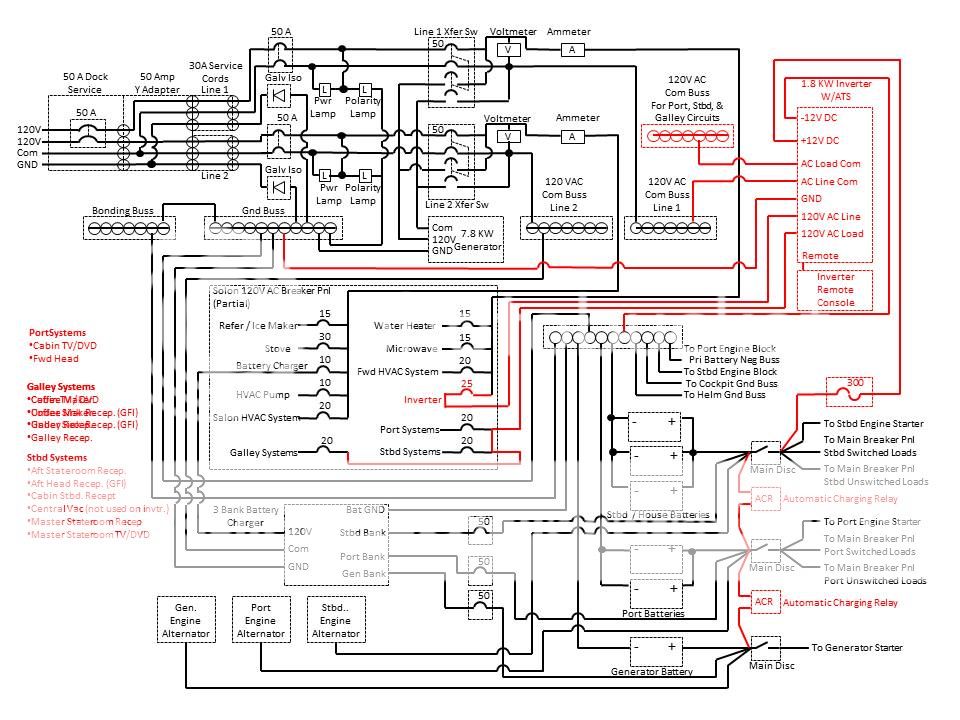

I'm buying a 2007 310 Sundancer that came with a factory generator. We plan to overnight a fair amount on it away from shore power and I'd like the convenience of running AC power for light loads without running the generator every time.

What I'm not seeing in looking at the boat's power panel in the cabin is an obvious way to do it right and easy.

The "right" way (and which matches most maker's manuals) is to feed the inverter as a circuit off the main AC panel and then feed its outputs to a sub-panel which then feeds the outlets/devices you want to power. The downside for this is at least in my 310 is that there's very little room to add a subpanel. Most of the extra space in the "control panel" enclosure is taken up by radio, CD changer, DVD player. I also don't know how much free wire existing circuits have to be moved to a new breaker -- having to rewire existing circuits would be a big headache.

Are the breakers on these panels wired individually (similar to a switch) or on a common snap-in bus like a standard dry land circuit panel?

If they are wired individually (screw terminal bus bar -> breaker -> load) then it would simplify inverter installation a lot -- send the inverter output -> single 20A breaker -> screw terminal bus bar -> existing accessory breaker/switches. I can fit a single 20A pushbutton breaker in the control panel blank space easily.

What I'm not seeing in looking at the boat's power panel in the cabin is an obvious way to do it right and easy.

The "right" way (and which matches most maker's manuals) is to feed the inverter as a circuit off the main AC panel and then feed its outputs to a sub-panel which then feeds the outlets/devices you want to power. The downside for this is at least in my 310 is that there's very little room to add a subpanel. Most of the extra space in the "control panel" enclosure is taken up by radio, CD changer, DVD player. I also don't know how much free wire existing circuits have to be moved to a new breaker -- having to rewire existing circuits would be a big headache.

Are the breakers on these panels wired individually (similar to a switch) or on a common snap-in bus like a standard dry land circuit panel?

If they are wired individually (screw terminal bus bar -> breaker -> load) then it would simplify inverter installation a lot -- send the inverter output -> single 20A breaker -> screw terminal bus bar -> existing accessory breaker/switches. I can fit a single 20A pushbutton breaker in the control panel blank space easily.