- Jun 5, 2016

- 5,590

- Boat Info

- 410 Sundancer

2001

12" Axiom and 9" Axiom+ MFD

- Engines

- Cat 3126 V-Drives

Looking to add EZ-Oil valves to the coolant J-Pipe on the 3126's to make the draining process easier, and more importantly, less messy. Since I'm planning to drain, clean and refill, I'll have to drain several times for each engine. Hoping this makes it easier/cleaner. Added similar valves to the transmissions and now thats a 10 minute job with no mess.

Here's my plan.

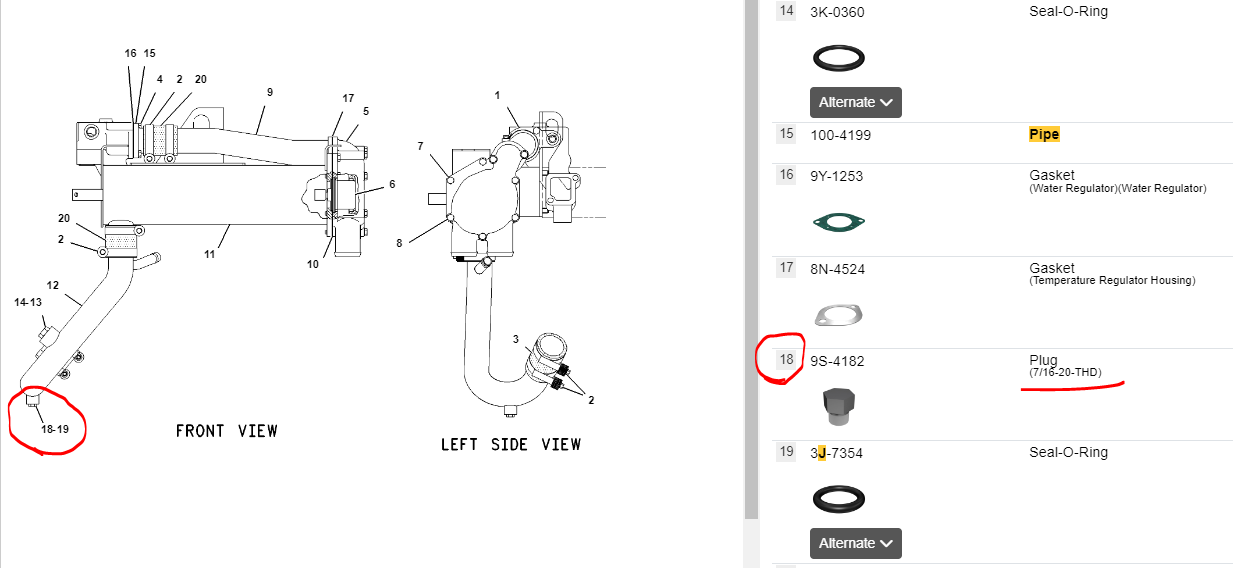

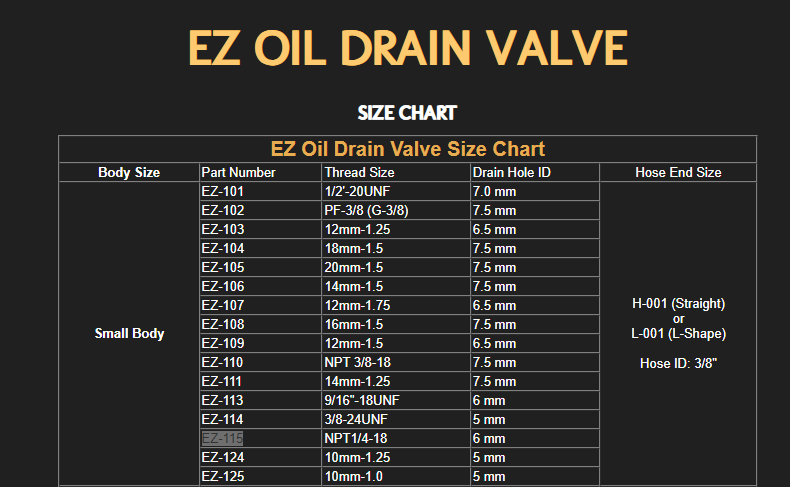

CAT Lists the plug in the J-Pipe as 7-16"-20 and its usually a UN or SAE straight thread with an o-ring sealing it up. The adapter listed below mates the SAE 7/16"-20 to 1/4" NPTF and that mates up to the EZ-115 EZ-Oil valve that has a 1/4-18 thread. I have a choice of steel ($7)or stainless for $20. I'm thinking stainless, but having dissimilar materials is a consideration, so looking for feedback on the material choice.

Anybody thought about this or already done this? Part #? Thoughts?

Here's my plan.

CAT Lists the plug in the J-Pipe as 7-16"-20 and its usually a UN or SAE straight thread with an o-ring sealing it up. The adapter listed below mates the SAE 7/16"-20 to 1/4" NPTF and that mates up to the EZ-115 EZ-Oil valve that has a 1/4-18 thread. I have a choice of steel ($7)or stainless for $20. I'm thinking stainless, but having dissimilar materials is a consideration, so looking for feedback on the material choice.

Anybody thought about this or already done this? Part #? Thoughts?