D Bell

Active Member

You may be getting air in the system before the pump. That would explain the no water at idle and water flow at 1,000 rpm.

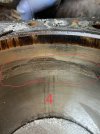

As Bill mentioned……it is something simple. The pump could even have a crack in it.

Just did the clear vinyl hose trick:

at idle - nothing

at 1,000 - gurgling flow

at 2,000 - good flow but bubbly

Air ingestion or blockage?