Cocktail Time

Well-Known Member

- Jul 9, 2007

- 1,208

- Boat Info

- 1998 400 Sundancer, Garmin 840xs GPS, Furuno Radar, B&G GPS pilot etc.

- Engines

- Cat 3116's, Westerbeke 7.6 BTD

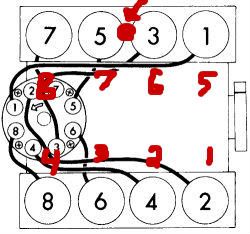

Alright, I'm looking for an easy answer that my mechanic and I are overlooking. I have a problem with my port motor but it seems strange they happened at the same time and rather than just repair and forget about it, I'm trying to figure out the cause; Symptoms are:

1.Low compression in #6 and #7 (68, 78)

2.#6 spark plug is bent.

3. No sign of overheating and plugs do not look exposed to coolant...

We are assuming the head gasket failed, that explains the low compression. But how the plug got bent is bugging me. Any recommendations on the things to look at? I'm hoping the #6 cylinder is ok, no wrist pin issues. We are going to remove head, check to make sure it is not warped, do valve job, then re-assemble. If you can think of something we're missing, let me know...Thanks! Dan

1.Low compression in #6 and #7 (68, 78)

2.#6 spark plug is bent.

3. No sign of overheating and plugs do not look exposed to coolant...

We are assuming the head gasket failed, that explains the low compression. But how the plug got bent is bugging me. Any recommendations on the things to look at? I'm hoping the #6 cylinder is ok, no wrist pin issues. We are going to remove head, check to make sure it is not warped, do valve job, then re-assemble. If you can think of something we're missing, let me know...Thanks! Dan