Indiana

Member

- Apr 12, 2018

- 44

- Boat Info

- Sundancer 290 1992

- Engines

- Twin 170HP Mercruser Inboard Engines

Hi,

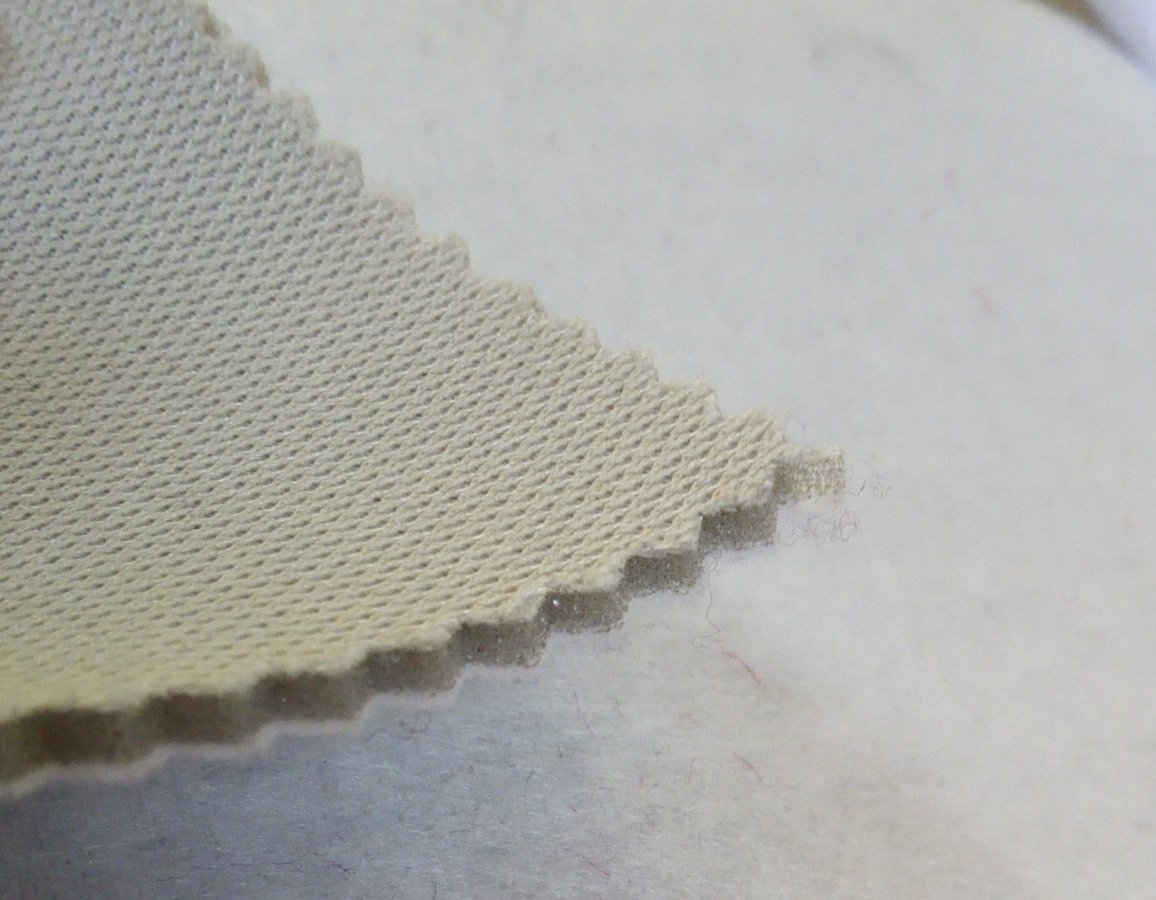

I am about to buy 8 meters of scrim-backed, 2mm foam-backed automotive headlliner, but would like to know first if you think it would be suitable as a cabin headliner on my SeaRay.

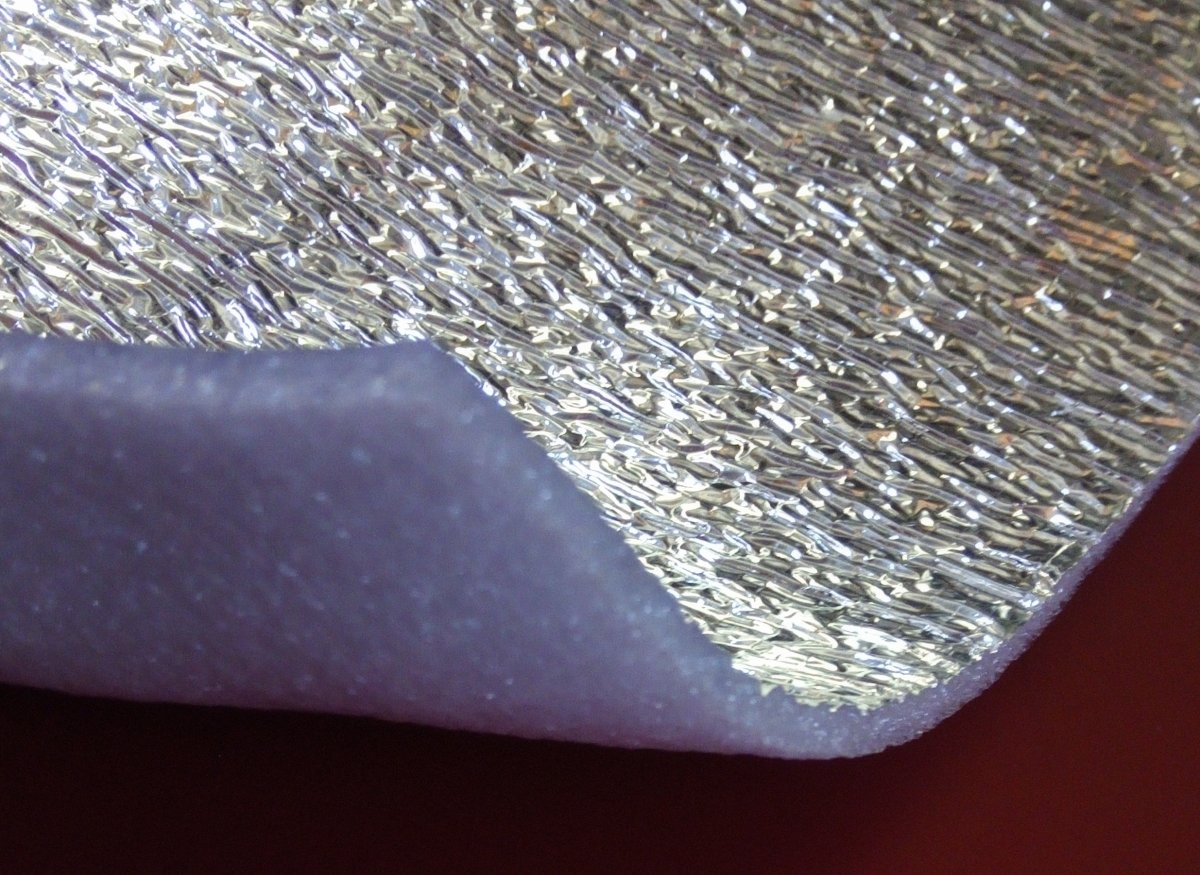

It will not be glued directly to the GRP, as I have already glued rolls of 3mm foam-backed insulation to the GRP (The automotive headliner will be glued to this).

I can't see a problem myself, and maybe this is a stupid question, but we learn as we go on.

Many thanks,

Indy

Photos of each attached.

I am about to buy 8 meters of scrim-backed, 2mm foam-backed automotive headlliner, but would like to know first if you think it would be suitable as a cabin headliner on my SeaRay.

It will not be glued directly to the GRP, as I have already glued rolls of 3mm foam-backed insulation to the GRP (The automotive headliner will be glued to this).

I can't see a problem myself, and maybe this is a stupid question, but we learn as we go on.

Many thanks,

Indy

Photos of each attached.