I'm planning on installing a hydraulic step under my swim platform. The "standard" way to attach it is to through-bolt it from the top with nuts below. However, I'm not too keen on a large number of bolts on the platform so I'm looking for other options.

So far I've come up with attaching 3-4" wide x 1/4" thick aluminum plate to the underside of the platform, then tapping it for bolts that would hold the platform. My current challenge is how do I secure the aluminum to the underside of the platform. The platform is cored with 1.5" Airex core, and vacuum infused.

A couple ideas so far. All of the below would be in addition to using some 5200:

Any thoughts if any of these are good / bad ideas, or some other idea, quite welcome.

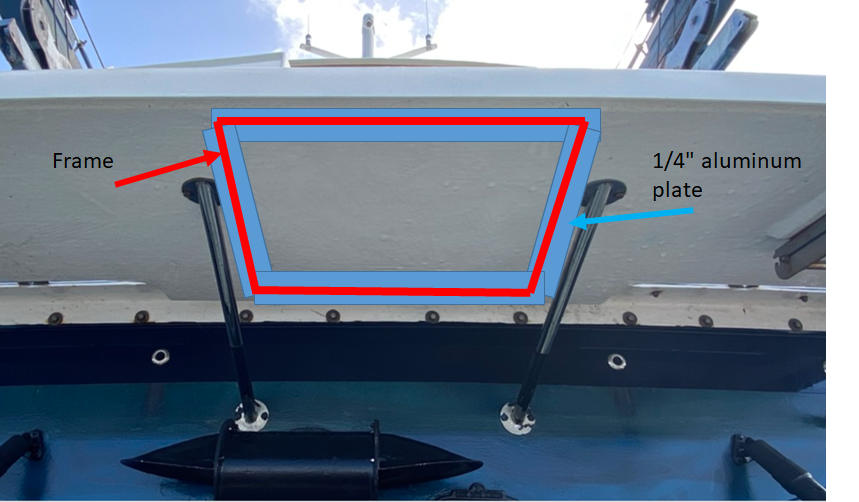

This is a pic of the underside of my swim platform, and a mockup of the what I'm thinking.

Pic of the step in a boat show display. Shows the rails and many attachment points.

CAD drawing of step.

So far I've come up with attaching 3-4" wide x 1/4" thick aluminum plate to the underside of the platform, then tapping it for bolts that would hold the platform. My current challenge is how do I secure the aluminum to the underside of the platform. The platform is cored with 1.5" Airex core, and vacuum infused.

A couple ideas so far. All of the below would be in addition to using some 5200:

- Pop rivets. Use some large-ish aluminum or stainless closed-end pop rivets. Would need a line of them down each side of the aluminum plate, spaced 4" apart or so. Drill into the plate, through the fiberglass, and rivet. Not sure if the fiberglass is strong enough for a rivet?

- Rivnuts. Similar to a pop rivet, but allows to thread a bolt in to hold the plate in place. Similar question to the pop rivet - is the fiberglass strong enough to not be crushed by the rivet action?

- Jacknut. Kind of like a hollow wall anchor with fingers that spread out on the blind side. Might be easier on the fiberglass?

- Epoxy in a bolt anchor. Haven't gotten this one all worked out yet.

Any thoughts if any of these are good / bad ideas, or some other idea, quite welcome.

This is a pic of the underside of my swim platform, and a mockup of the what I'm thinking.

Pic of the step in a boat show display. Shows the rails and many attachment points.

CAD drawing of step.