JamesT

Active Member

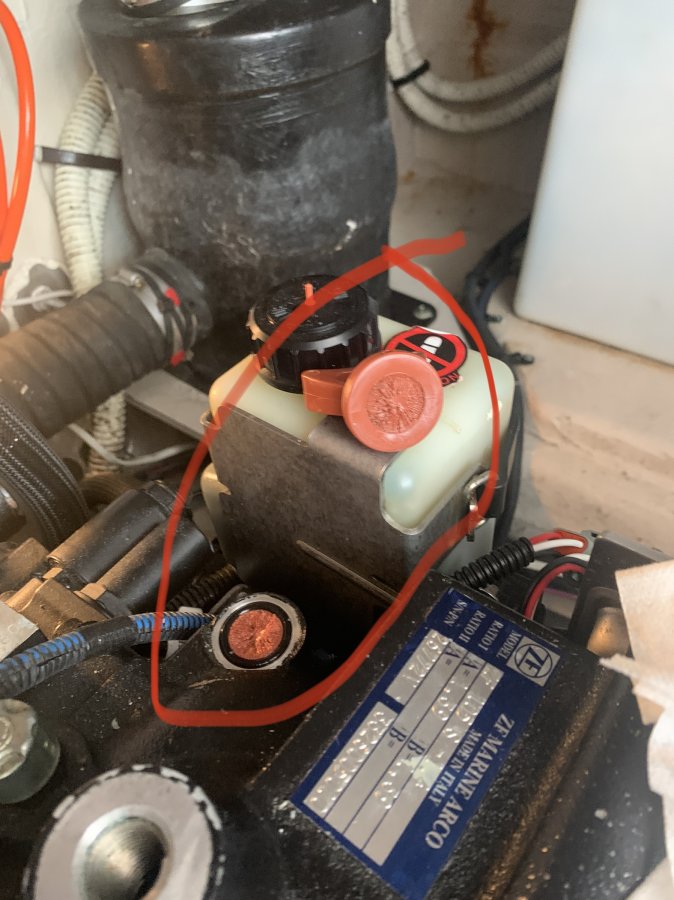

This is what I get for always checking my fluids! Any ideas how to unscrew the dipstick without the handle?

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature currently requires accessing the site using the built-in Safari browser.

I like the heat up a screwdriver idea! I was going to drill some holes in it to get a screwdriver into it.Can you just tap it with a punch and hammer out toward the edge to unscrew it or put a groove in it to use a screw driver.... maybe heat up a screw driver

I thought of that but don’t want to risk the epoxy seeping out the sides and bonding it.Reattach the handle with some JB Weld quick or 5 minute epoxy.

Heat from dremel spin may end up melting the plastic and get too goopy. I will first test the hot screwdriver on the head, I could probably drill two holes a centimeter apart and stick tips of needle nose pliers and unscrew.I was thinking a dremel tool to cut a slot into the top, and use a screwdriver and a mallet to rotate to remove

Not a bad plan. Kind of like a spanner wrench.Heat from dremel spin may end up melting the plastic and get too goopy. I will first test the hot screwdriver on the head, I could probably drill two holes a centimeter apart and stick tips of needle nose pliers and unscrew.

Ask 10 economists what the future holds, and you'll get 12 answers. Ask 10 boaters how to fix something and you'll get at least 15 suggestions....Don’t anyone of you guys on this site ask how many ways there are to skin a cat

I checked the oil 10 seconds before the cap ripped off and I always drag the wet stick on the side on the way out so I’m sure the threads are lubed already. So disgusted that this happened at the end of an otherwise great weekend. Better than a mechanical failure of course, but seriously...WTF??!!Not a bad plan. Kind of like a spanner wrench.

If you use low speed on the dremel bit it should be OK. Depends on the plastic. There are a lot of types of dremel bit - flat cut off disks, carbide bits, diamond bits. All depends on what you have in your toolbox.

I would be very cautious about using a mallet at first. You really don't want to break anything else. I would reiterate to try to get some penetrating oil on the threads.

Not a bad plan. Kind of like a spanner wrench.

If you use low speed on the dremel bit it should be OK. Depends on the plastic. There are a lot of types of dremel bit - flat cut off disks, carbide bits, diamond bits. All depends on what you have in your toolbox.

I would be very cautious about using a mallet at first. You really don't want to break anything else. I would reiterate to try to get some penetrating oil on the threads.

I guess I should of said tap it with a mallet, common sense.... but I will say it now. Tap it with a rubber mallet....Yep no mallets or hammers. One wrong move on the housing and it’s a $10,000 mistake.

(Praying)2 self tappers close to each opposing edge, then use a screwdriver or similar across the self tappers as a key to rotate.