OK, I spent the last three days pulling the old hose from the master head and getting the new PVC pipe installed. There is about 3 feet of hose and all else is Schedule 40 PVC pipe and fittings. Some of the minor bends on the pipe were done with a heat gun to eliminate glued fittings. This was in the "Really Hard Bag" of things to do. Some pics for those with the 52DB that would like a challenge.

From the Head down into the Tunnel -

Through the Tunnel (the old hose was down on the floor, now the PVC is up along the ceiling)

Up from the tunnel into the storage area under the galley

Behind the Washer/Dryer -

Through the engine room bulkhead. The open hole was for the old hose; it was in a really bad location, I still need to get it sealed up -

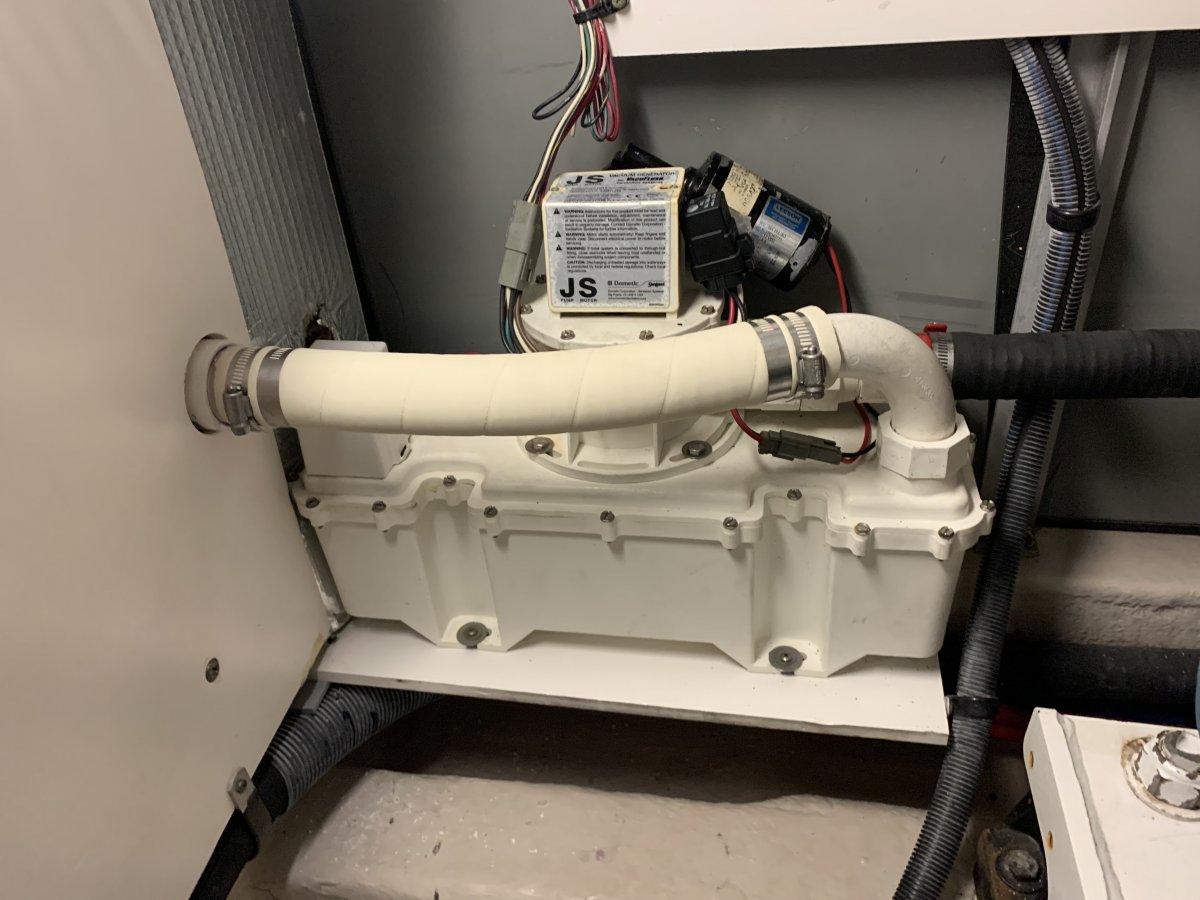

To the Vacuum Generator in the Engine Room -

From the Head down into the Tunnel -

Through the Tunnel (the old hose was down on the floor, now the PVC is up along the ceiling)

Up from the tunnel into the storage area under the galley

Behind the Washer/Dryer -

Through the engine room bulkhead. The open hole was for the old hose; it was in a really bad location, I still need to get it sealed up -

To the Vacuum Generator in the Engine Room -

Last edited: