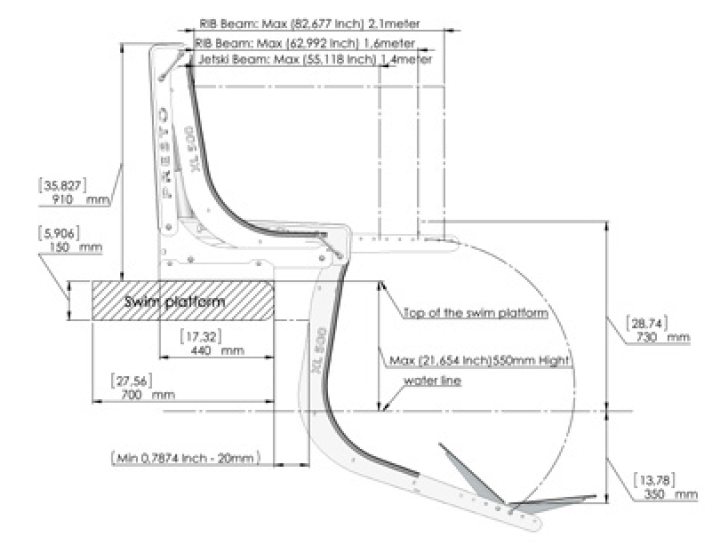

I thought I would provide some details on the installation of a Presto marine XL500 Davit on my 2006 52 Sedan Bridge.

Difficulty (1 to 10 with 10 being the most difficult):

A couple of things regarding the boat:

Here is a picture of the lift -

Difficulty (1 to 10 with 10 being the most difficult):

- From a technical difficulty aspect, it is about an 8.

- From an installation difficulty aspect, an 8.

- From a tool aspect (do I need speciality tools), an 8.

A couple of things regarding the boat:

- The swim platform on the 52DB is big and well reinforced underneath. Plenty deep for the installation of Presto's 42-inch rolling lift. This allows the dinghy to set aft of the platform or tucked tight into transom or in-between.

- Unique to the 52DB is the hull extends to the back of the swim platform and access under the platform is from the lazerette. So, all of the bolting and hydraulics are in dry areas.

- My boat has a large watermaker in the lazerette so there is little room for the hydraulic power pack. I had to get inventive for its installation.

Here is a picture of the lift -