- Oct 4, 2006

- 2,344

- Boat Info

- 2006 300DA Sundancer

- Engines

- 350 Mags / Bravo III

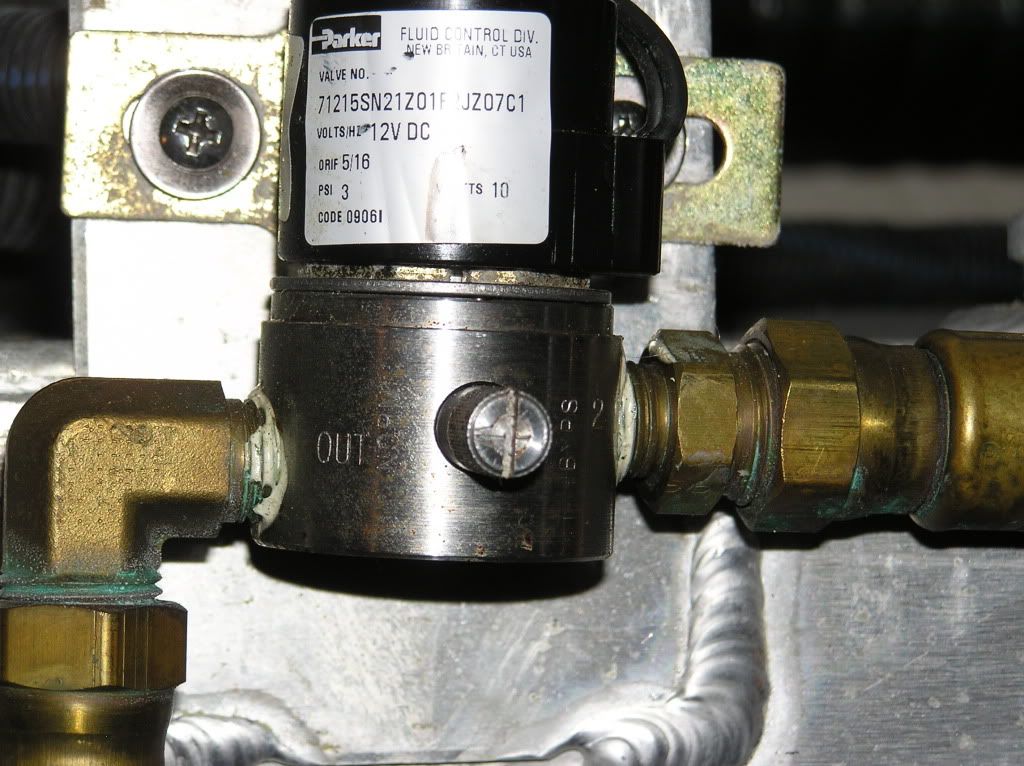

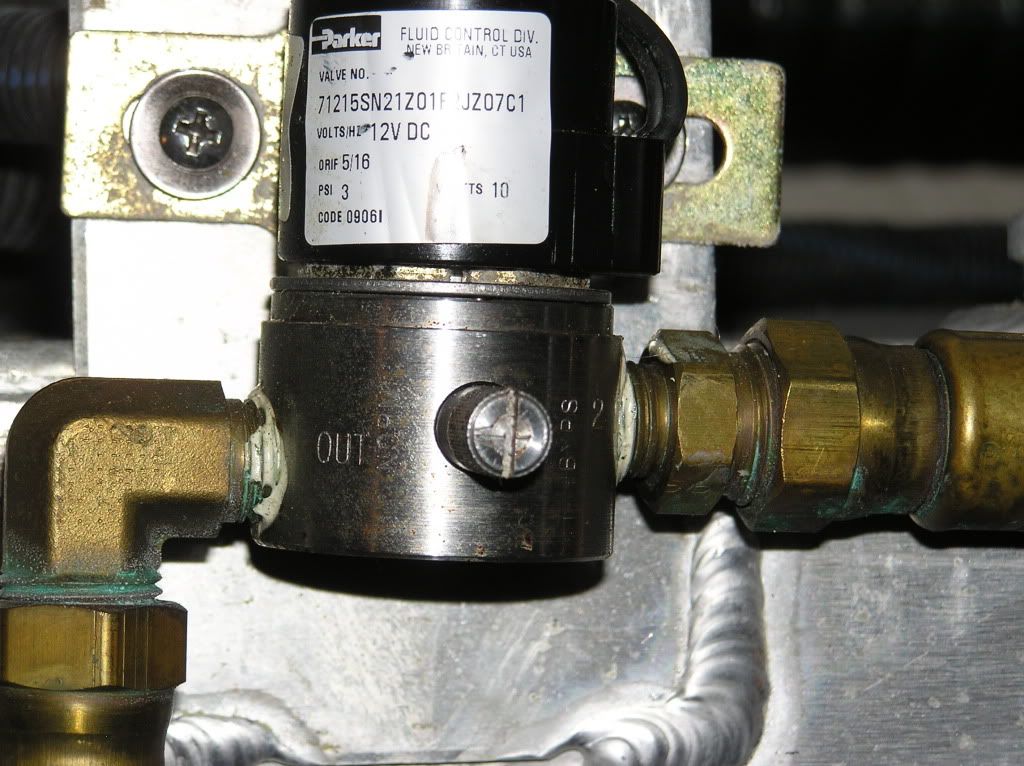

One of the features of the Parker / Skinner solenoid valve used on gasoline boats is often misunderstood when troubleshooting a fuel system. My hope is to illustrate where specific features are on the valve, and how to "manually overide" in the event the coil fails, or you suspect there is no fuel flow to the cool fuel filter system.

Below is the location of the fuel solenoid valves on my boat. The forward one is for the genset, the other is for the starboard engine. There is another on the port fuel tank so I have 3 of these little gems....

In this picture, look closely at the knurled knob's screwdriver slot. You will see an arrow stamped on the face that points to the left or towards the outlet. This arrow should be stamped on all Parker / Skinner valves with this type of manual overide. The screwdriver slot means absolutely nothing with relationship to fuel flow.

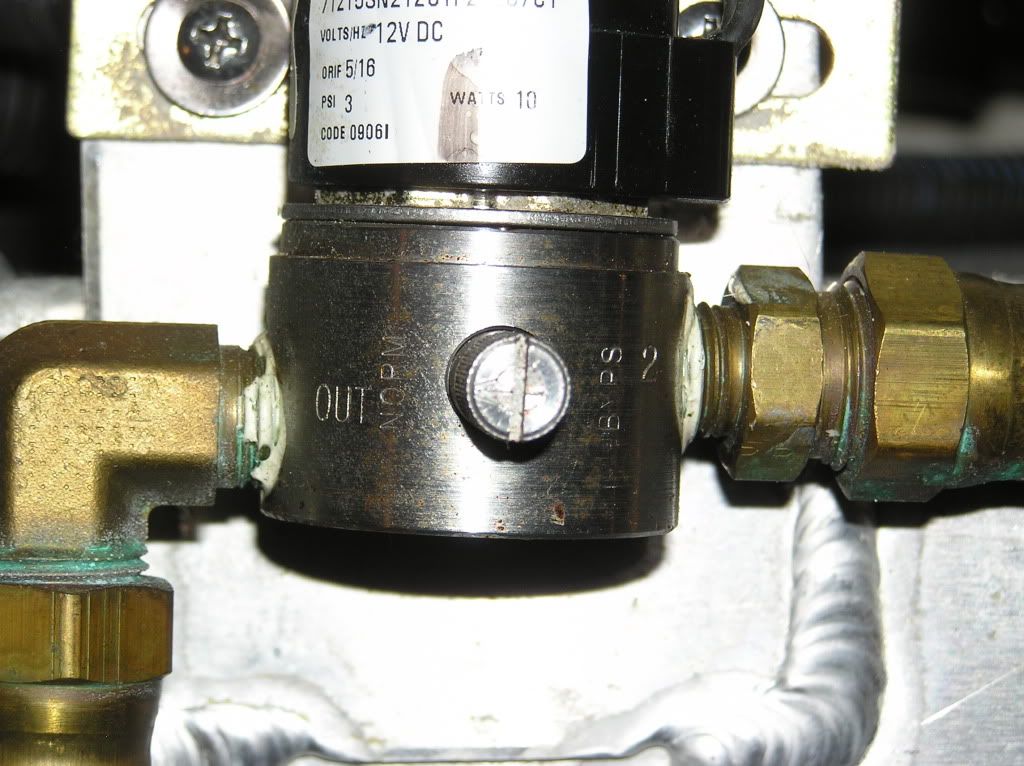

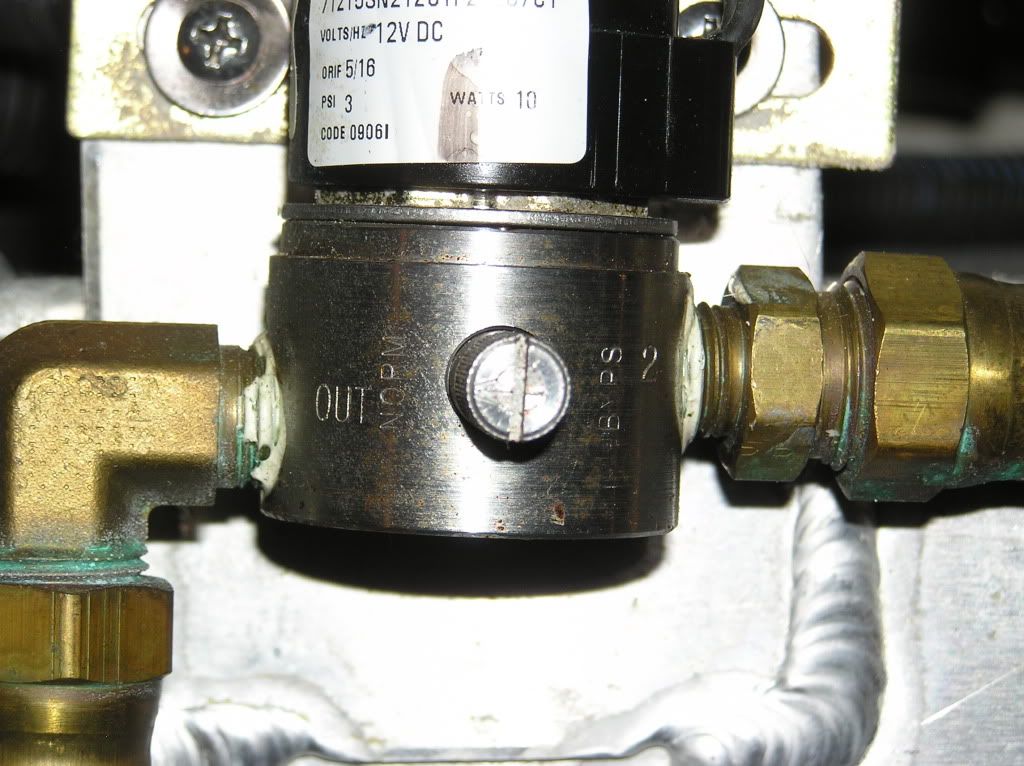

In this picture, look closely for the words "NORM" and "BYPASS" stamped on the valve body. Under normal operating conditions, the arrow should point to NORM, which just happens to be the flow path of the valve to the outlet.

If the coil has failed, (test for a magentic field by using a steel rule or small flat blade screwdriver, you should feel a magnetic pull toward the coil when the ignition switch is turned on or when there is 12 VDC present), turn the knurled knob 180 degrees CW until the arrow is pointing to the word BYPASS and stop. By doing this, you have internally moved the plunger off of its seat to allow fuel flow. The arrow point must point to the BYPASS postion on the valve body. Regardless how many times you turn the knob, it must point to BYPASS. You should be able to turn the knob with your fingers, the screwdriver slot position is irrelevant to overiding the internal plunger.

Keep this in mind, this valve only has a 5/16 orifice for the fuel to flow through. If something has breached any screen that may be on the fuel pickup, it is possible to restrict the orifice should something get caught in it. This contaminant can cause the internal plunger to hang up (stick).

Sea Ray part number for the solenoid valve is 1791155 per my 2006 300DA parts manual. I work for a Parker distributor, we are authorized for the Skinner product line. The model code on the tag suggests that it is a proprietary to an OEM because it doesn't follow the standard product offering. Therefore, I wouldn't suggest a substitute to attempt to cut cost if you need to replace it.

I spoke with a Skinner Tech Service Rep to confirm the overide method as described above. I hope this will take any mystery that may have surrounded this important component of the fuel system.

Below is the location of the fuel solenoid valves on my boat. The forward one is for the genset, the other is for the starboard engine. There is another on the port fuel tank so I have 3 of these little gems....

In this picture, look closely at the knurled knob's screwdriver slot. You will see an arrow stamped on the face that points to the left or towards the outlet. This arrow should be stamped on all Parker / Skinner valves with this type of manual overide. The screwdriver slot means absolutely nothing with relationship to fuel flow.

In this picture, look closely for the words "NORM" and "BYPASS" stamped on the valve body. Under normal operating conditions, the arrow should point to NORM, which just happens to be the flow path of the valve to the outlet.

If the coil has failed, (test for a magentic field by using a steel rule or small flat blade screwdriver, you should feel a magnetic pull toward the coil when the ignition switch is turned on or when there is 12 VDC present), turn the knurled knob 180 degrees CW until the arrow is pointing to the word BYPASS and stop. By doing this, you have internally moved the plunger off of its seat to allow fuel flow. The arrow point must point to the BYPASS postion on the valve body. Regardless how many times you turn the knob, it must point to BYPASS. You should be able to turn the knob with your fingers, the screwdriver slot position is irrelevant to overiding the internal plunger.

Keep this in mind, this valve only has a 5/16 orifice for the fuel to flow through. If something has breached any screen that may be on the fuel pickup, it is possible to restrict the orifice should something get caught in it. This contaminant can cause the internal plunger to hang up (stick).

Sea Ray part number for the solenoid valve is 1791155 per my 2006 300DA parts manual. I work for a Parker distributor, we are authorized for the Skinner product line. The model code on the tag suggests that it is a proprietary to an OEM because it doesn't follow the standard product offering. Therefore, I wouldn't suggest a substitute to attempt to cut cost if you need to replace it.

I spoke with a Skinner Tech Service Rep to confirm the overide method as described above. I hope this will take any mystery that may have surrounded this important component of the fuel system.

Last edited: