bbwhitejr

Well-Known Member

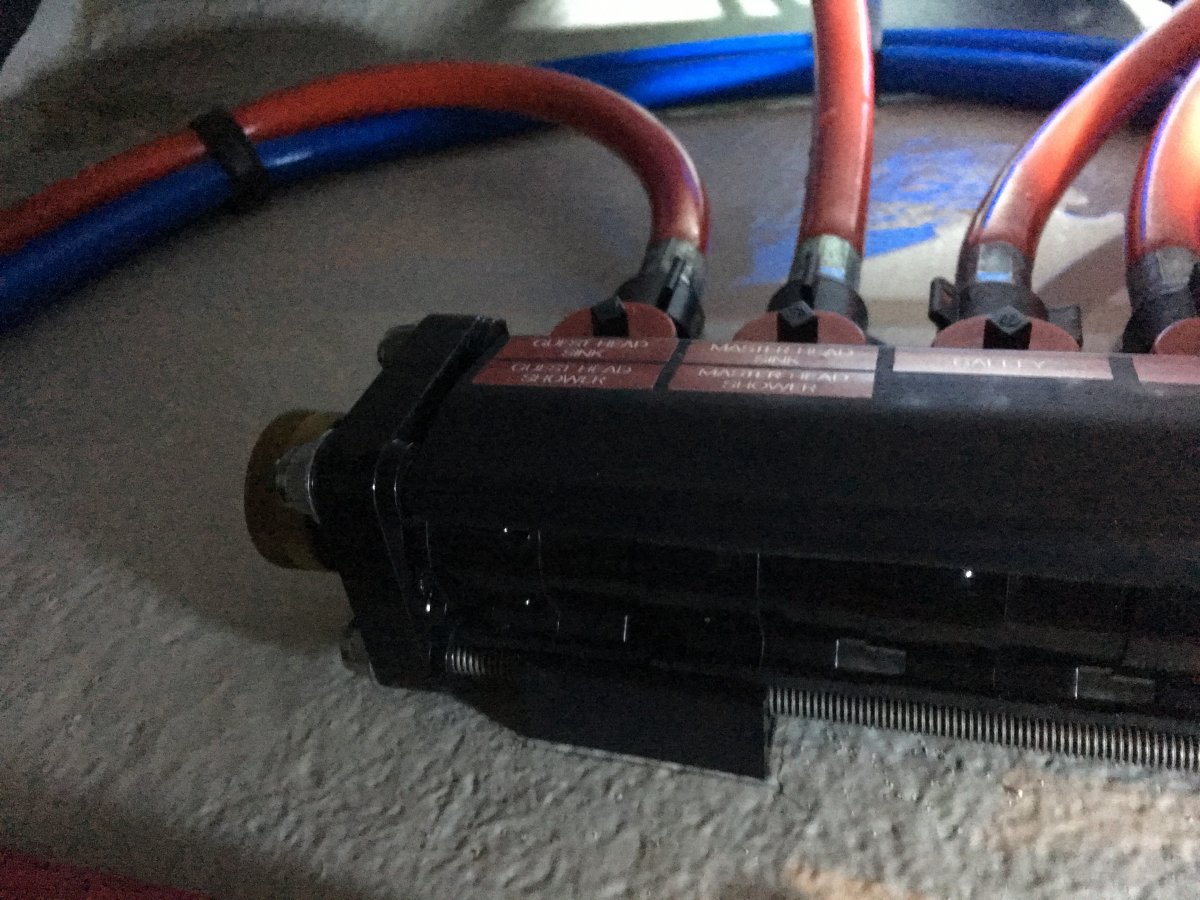

Anyone have any experience with SeaTech Marine Uniflex hoses and fittings? I have some that are dripping at times at the 1/2” hose connection. There is nothing wrong with the hose, but the connections drip. I can buy the hoses with the hose connections attached, but they are not cheap and I only need stop the drip. There are no hose washers that I can see.

Any advice welcomed. Here is a pic.

Thanks,

Bennett

Any advice welcomed. Here is a pic.

Thanks,

Bennett

Last edited: