Jerzey Jeff

New Member

- Apr 20, 2016

- 3

- Boat Info

- 2000 290 Amberjack

- Engines

- Twin 260 Mercs with Bravo III outdrives

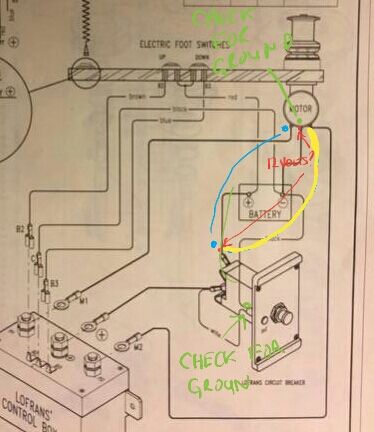

I've read a lot of windlass threads. I'm still stumped on why our Sea Ray 2000 290 Amberjack windlass (Lofrans Progress 1) has stopped working.

The facts:

1. I did not know I was supposed to tie off the chain to the cleat to take pressure off the windlass. And we were pulled along in the wind several times, causing stress for both us and the windlass.

2. The windlass motor "slowly" died. whu-whu-whu-whu-whu......whu-whu......whuh. (while attempting to bring it in).

3. The control box is still clicking from helm switch, and nothing from up/down foot controls.

4. I took control box apart. Sanded the contacts, but it was in mint condition.

5. The red, round, 105A breaker in the DC breaker panel - port side, cockpit wall (next to battery switches) seems to be OK, as (like any trained monkey) I pushed it in an effort to reset in case it had tripped.

6. 3 batteries on board - 13.3, 13.4, 13.5 DC volts. They fire up engines no sweat. (multimeter works)

6. If there is an additional breaker or fuse in the circuitry, it is not apparent, and not shown on the wiring diagram. Not in the engine room, nor in the anchor locker. I just can't find it if it exists.

7. I confirmed continuity on the 3 or four connections from windlass motor to control box that I could actually reach (you need to be a contortionist to get in that locker)

8. Most important fact is that I'm not electrically inclined.

Anyone???

Not sure how to attach photos yet. Will work on that.

Jerzey Jeff

The facts:

1. I did not know I was supposed to tie off the chain to the cleat to take pressure off the windlass. And we were pulled along in the wind several times, causing stress for both us and the windlass.

2. The windlass motor "slowly" died. whu-whu-whu-whu-whu......whu-whu......whuh. (while attempting to bring it in).

3. The control box is still clicking from helm switch, and nothing from up/down foot controls.

4. I took control box apart. Sanded the contacts, but it was in mint condition.

5. The red, round, 105A breaker in the DC breaker panel - port side, cockpit wall (next to battery switches) seems to be OK, as (like any trained monkey) I pushed it in an effort to reset in case it had tripped.

6. 3 batteries on board - 13.3, 13.4, 13.5 DC volts. They fire up engines no sweat. (multimeter works)

6. If there is an additional breaker or fuse in the circuitry, it is not apparent, and not shown on the wiring diagram. Not in the engine room, nor in the anchor locker. I just can't find it if it exists.

7. I confirmed continuity on the 3 or four connections from windlass motor to control box that I could actually reach (you need to be a contortionist to get in that locker)

8. Most important fact is that I'm not electrically inclined.

Anyone???

Not sure how to attach photos yet. Will work on that.

Jerzey Jeff

Last edited: