89P270

Active Member

- Feb 2, 2017

- 209

- Boat Info

- 1989 Pachanga 270

1997 270DA

- Engines

- Twin Mercruiser 357 4V alpha's

As promised, here is my run at repainting the upper Drive and lower gear cases on one of the two Bravo IIIs I have stored. This (and another) came off my 2002 Rinker 342 Fiesta Vee that was equipped with dual 6.2L MX and Bravo Three’s. I repowered and I kept these for future use. These are 2.2:1 drive ratio and had only 263 total hours on them. I will be using these as spare for my 97 270 DA with 454/Bravo III.

Here is the drive before I started. Note most the pitting is on the upper “drive” gear housing which corresponds to the water line and slightly above and below the water line. Some of the dimpling is up to 1/8 inch deep. BTW "Brash" should be "Brass"

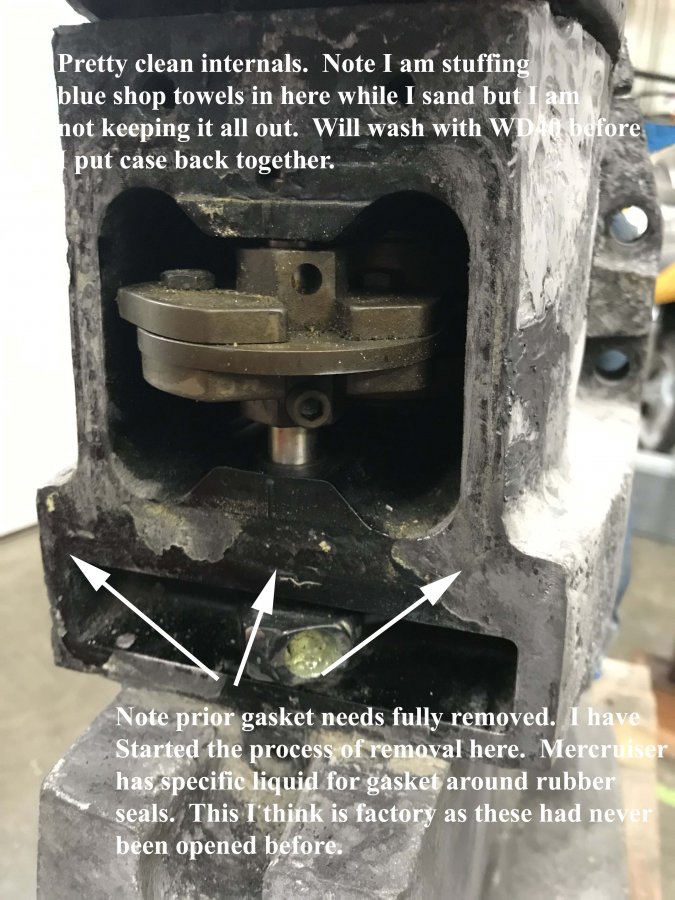

I opened the covers on the upper drive case before I started and it looks pretty clean so worth the repair effort.

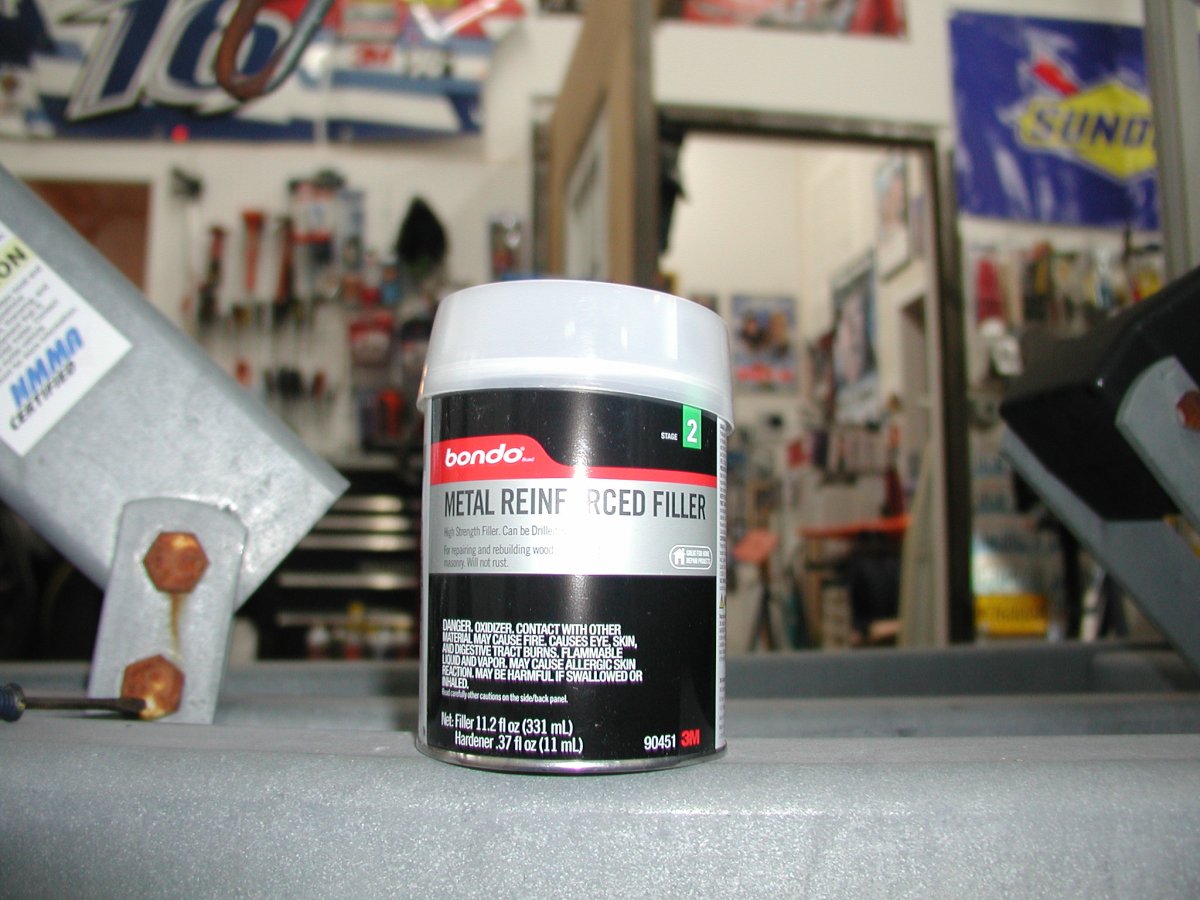

After researching a bunch on how to fill the corrosion pits, I elected to try both Marine JB Weld and Bondo Metal reinforced filler. Be carefull with the Bondo mixing, too much liquid and it cures WAY fast. Pin hole the catalyst bottle for small drops rather than a larger hole.

I prepped the surface of the drive/gear casings with 80 grit and a brass wire brush. I actually got a cordless drill disc sanding kit at Harbor freight ($14) and its done very very well. I started by hand sanding but now, I will only use the discs on low rotation.

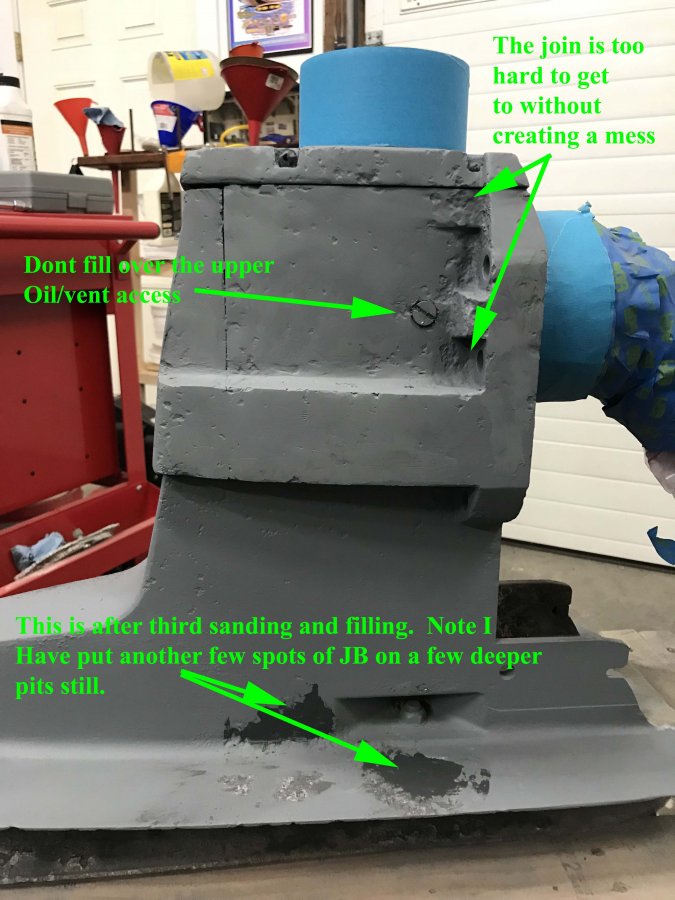

So, here is a series of photos showing first, second, and third filling on Starboard side. Note its getting smoother and smoother the more effort I put in. I am using Mercruiser primer between fillings to support leveling but am careful to remove primer where I am putting second and third applications of JB or Bondo.

So this is as far as I have gotten so far. I now have three weeks work in the field at JBLM and then back to it. I will update as I build up edges on the lower case as well as show with the Phatom Black once I get there.

One thing I want to hear from others out there, what is your experience with the Mercruiser clear top coat. I plan to put on Phatom Black over the Mercruiser primer but some have said not to use topcoat as it weathers dull. I would like to have a nice gloss black for at least 2 years before I have to maintenance these again. Thoughts and photos welcome.

Here is the drive before I started. Note most the pitting is on the upper “drive” gear housing which corresponds to the water line and slightly above and below the water line. Some of the dimpling is up to 1/8 inch deep. BTW "Brash" should be "Brass"

I opened the covers on the upper drive case before I started and it looks pretty clean so worth the repair effort.

After researching a bunch on how to fill the corrosion pits, I elected to try both Marine JB Weld and Bondo Metal reinforced filler. Be carefull with the Bondo mixing, too much liquid and it cures WAY fast. Pin hole the catalyst bottle for small drops rather than a larger hole.

I prepped the surface of the drive/gear casings with 80 grit and a brass wire brush. I actually got a cordless drill disc sanding kit at Harbor freight ($14) and its done very very well. I started by hand sanding but now, I will only use the discs on low rotation.

So, here is a series of photos showing first, second, and third filling on Starboard side. Note its getting smoother and smoother the more effort I put in. I am using Mercruiser primer between fillings to support leveling but am careful to remove primer where I am putting second and third applications of JB or Bondo.

So this is as far as I have gotten so far. I now have three weeks work in the field at JBLM and then back to it. I will update as I build up edges on the lower case as well as show with the Phatom Black once I get there.

One thing I want to hear from others out there, what is your experience with the Mercruiser clear top coat. I plan to put on Phatom Black over the Mercruiser primer but some have said not to use topcoat as it weathers dull. I would like to have a nice gloss black for at least 2 years before I have to maintenance these again. Thoughts and photos welcome.