Alex F

Well-Known Member

- Nov 14, 2006

- 9,166

- Boat Info

- 2005 420DB with AB 11 DLX Tender, Raymarine Electronics (2x12" MFDs) with Vesper AIS

- Engines

- Cummins 450Cs, 9KW Onan Generator, 40HP Yamaha for tender.

Hey guys,

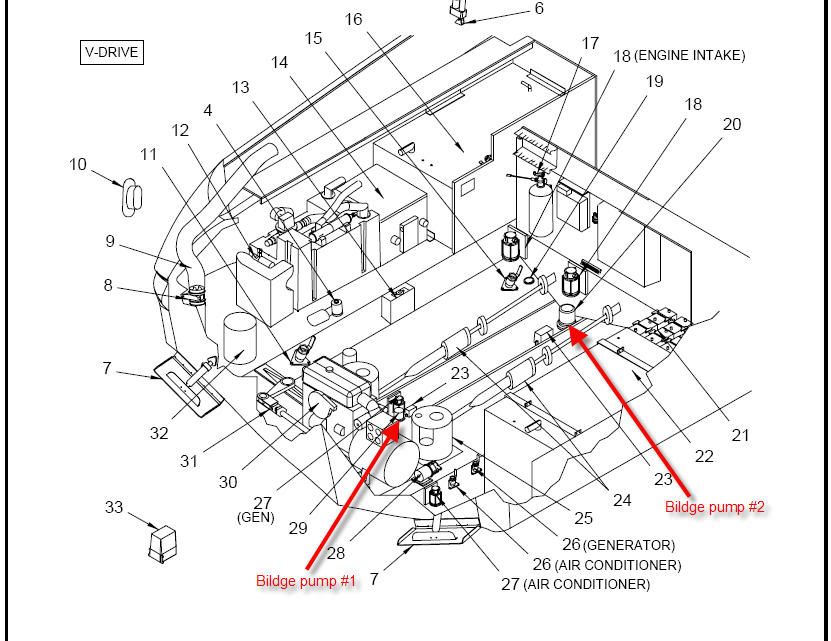

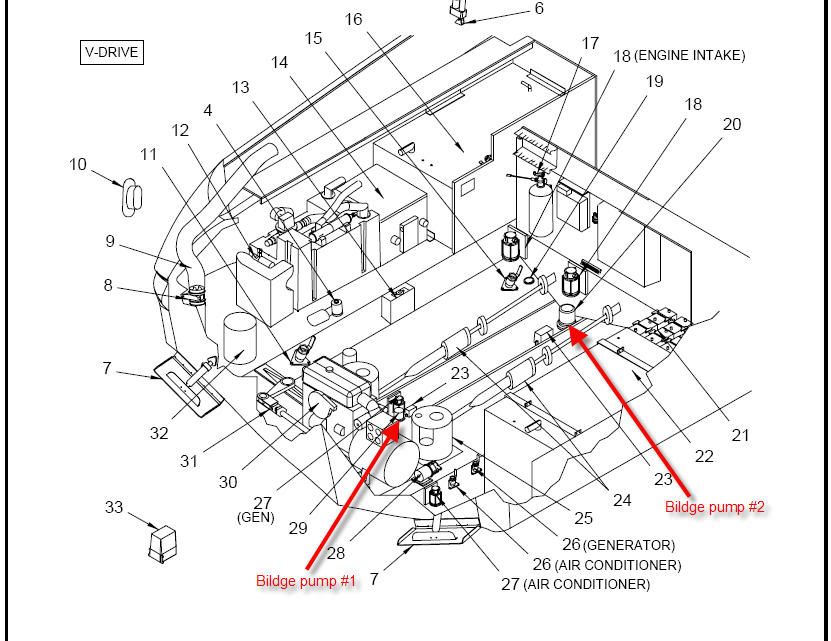

I tried searching but found nothing helpful. I’ll be doing more testing, but I may have to replace my bilge pumps. So far I was able to find my way to most of the items that I had to service, but bilge pumps got me scratching my head as a can’t find a way to get close enough to be able to replace either pump. Did anyone have done it successfully as a DIY?

I tried searching but found nothing helpful. I’ll be doing more testing, but I may have to replace my bilge pumps. So far I was able to find my way to most of the items that I had to service, but bilge pumps got me scratching my head as a can’t find a way to get close enough to be able to replace either pump. Did anyone have done it successfully as a DIY?

Last edited: