mrsrobinson

Well-Known Member

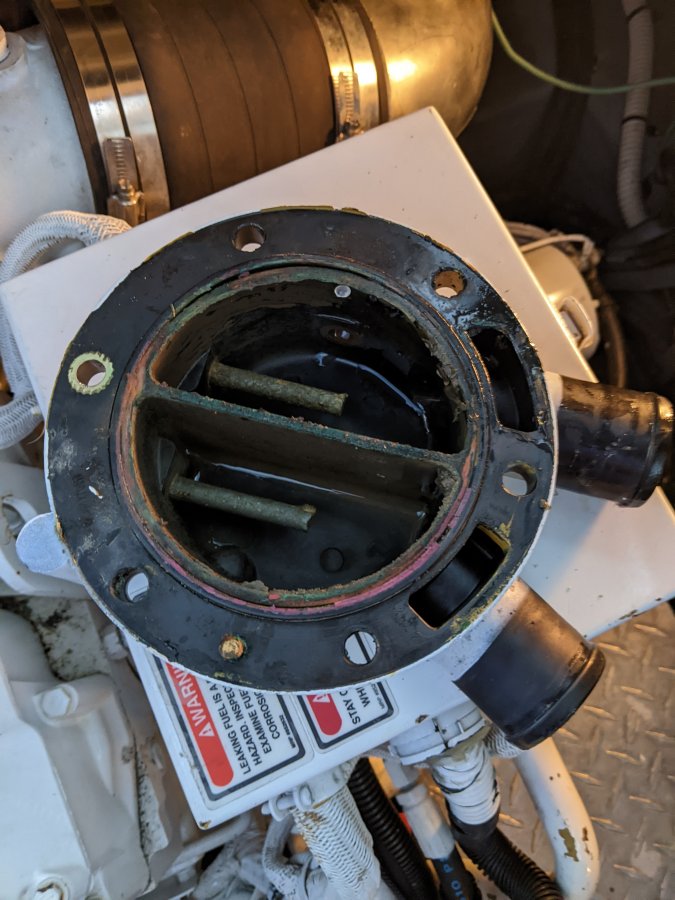

I pulled the cap off of the port one and it was clean, with the exception of the small pieces of rubber you see at the bottom, which I pulled out.

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature currently requires accessing the site using the built-in Safari browser.

Yes, that was and still is the plan, running the boat in mud and overheating the engines was never part of that plan though. I'd like to focus on getting this resolved while at the same time continuing with service.Greg,

You have stated that this is a boat with no significant documented service history, a situation similar to mine.

Your boat is over 20 years old.

Why not just go through all the systems and bring them back to standards?

Seems to me you will gain reliability and safety and reduce unexpected, very costly issues taking this route rather than chasing problems as they come up.

Just MHO.

BEST !

RWS

Thank you, this is what I need to hear having never looked at one myself. I'm hearing you say it it looks clogged with mud, not that it needs descaling, correct? To refresh everyone's memory the boat ran flawlessly for 12 hours after we took ownership, and before we turned into our new marinas creek. and sucked up mud. Temperatures never got above 180° until after this event.That heat exchanger is almost 50% clogged. That is horrible. It travels from the bottom. Across then back at the top. The top half that looks clean is the return. That will most certainly affect engine temp. I think you found the source of the problem

GEAR or GEARS also refers to the TRANSMISSION.

Not trying to beat a dead horse here, however IMHO, I wouldn't spend a dime servicing those 20 year old saltwater exposed gear coolers with no service history.

You saw the pics I posted of mine - you should have seen what was growing in the risers/showerheads.

Everything is now squeaky clean, aftercoolers included.

Even if my 26 year old gear coolers looked perfect - I WOULD HAVE STILL CHANGED THEM

Next weekend I'll add the freshwater flush/SALT AWAY plumbing and will make this issue disappear for good !

Did this practice on my last diesel boat - never had to remove or service any of the coolers.

Just MHO and I practice what I preach.

BEST !

RWS

Looking at these pictures I would be concerned with my bonding system and asking - why aren't my zinc's being consumed.For me, the transmission cooler was 25 years old with an UNKNOWN saltwater service history.

Let's see...... cost of replacing transmission due to seawater intrusion vs cost of cleaning 25 year old cooler vs cost of new cooler........

I did the math and took the advice of Dr. Webster......

REPLACED THE COOLERS.

View attachment 129930 View attachment 129931 View attachment 129932 View attachment 129933

Looking at these pictures I would be concerned with my bonding system and asking - why aren't my zinc's being consumed.

I would. You must have less than 1 ohm between every metal object that sees raw water and the bolt to the zinc on the transom.>>>>>>>>>>>>>>>>>>>>>

Good point Tom.

She was a dock queen and other than oil changes & zincs, not a lot of attention was given to the engine room.

When I removed the coolers I cleaned every engine bonding wire with a die grinder then put some dielectric grease on each connection.

Perhaps I should also check for continuity between the engine's ground and the bonding system?

RWS

I would. You must have less than 1 ohm between every metal object that sees raw water and the bolt to the zinc on the transom.

That is a "dynaplate" and serves to establish a static ground for electronics and lightning protection. It is bonded also but not a component of the galvanic protection.>>>>>>>>>>>>>>>>>>>>>>

Thank you.

Still LEARNING this vessel.

What part does the plate in bottom of the hull, facing downward (not the transom zinc) play in the system?

Should that be a part of the bonding test as well?