- Sep 25, 2016

- 1,252

- Boat Info

- 300 Sundancer 1994, trailered tri-axle LoadRite roller

- Engines

- Mercruiser 5.7 260HP Alpha One Gen II, twin

S.O.P for me:

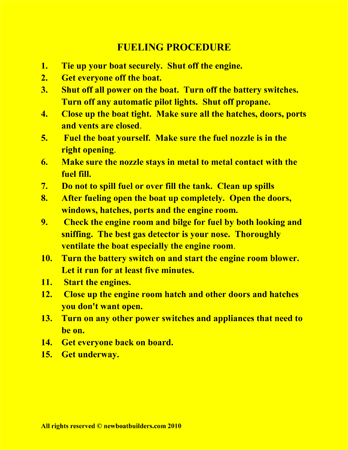

Raise hatch/smell test

Blowers on for a full 4 to 5 minutes.

Start genset.

Start Engines.

Lower Hatch.

Blowers stay on until we return to the dock and are the last things off.

The fumes from 1/4 cup of gasoline are equal to 15 sticks of dynamite...

This is my routine EVERY time I leave the dock and EVERY time after I refuel.

Leave them running till back at the dock or anchored.

If I shutdown the engines, I'll leave the blowers running for a few minutes for cool down.

@Waterlife,

Intake should be high in compartment, cool air in.

Exhaust hoses as low as possible fumes out, (gas is heavier than air)