Something to think about - IAC's will tend to gum up from oils, dirt, and carbon. As long as they are warm they will work just fine as the rotating or sliding valve can move freely and rapidly when the system demands a specified position. In cold conditions the oils and gumming will become less viscous and cause the valve positioning to stick or be slow and affect the engine's capability to achieve a stable idle. Cleaning them may fix the issues.

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature currently requires accessing the site using the built-in Safari browser.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

surging (hunting) idle when cold....

- Thread starter CliffA

- Start date

CliffA

Well-Known Member

- Dec 29, 2009

- 4,712

- Boat Info

- 2001 Sea Ray 340DA

Name: 'Happy Place'

4.5kW West. Generator

Purchased Nov. 2014

Fresh Water Use

- Engines

- Twin Merc. 6.2L (MPI)

640 hp (Total)

Raw Water Cooled

V-Drive Transmissions

Something to think about - IAC's will tend to gum up from oils, dirt, and carbon. As long as they are warm they will work just fine as the rotating or sliding valve can move freely and rapidly when the system demands a specified position. In cold conditions the oils and gumming will become less viscous and cause the valve positioning to stick or be slow and affect the engine's capability to achieve a stable idle. Cleaning them may fix the issues.

excellent thought....makes a lot of sense...thanks....I will check and clean them this WE.....

cliff

CliffA

Well-Known Member

- Dec 29, 2009

- 4,712

- Boat Info

- 2001 Sea Ray 340DA

Name: 'Happy Place'

4.5kW West. Generator

Purchased Nov. 2014

Fresh Water Use

- Engines

- Twin Merc. 6.2L (MPI)

640 hp (Total)

Raw Water Cooled

V-Drive Transmissions

does anyone know if i can manually extend the sliding valve of an IAC so that I can fully extend it out to clean the entire shaft of the valve?.....if not any ideas how to get it to fully extend?....

thanks....

cliff

thanks....

cliff

I don't think so; I believe the Mercury IAC's are PCM driven stepper motors and can only be positioned using the ECU. Maybe simply remove the IAC and look in it to see how crapped up it is and clean with a good aerosol carburetor cleaner. Might have to spray some in, let it set for a while, then flush out with more cleaner.does anyone know if i can manually extend the sliding valve of an IAC so that I can fully extend it out to clean the entire shaft of the valve?.....if not any ideas how to get it to fully extend?....

thanks....

cliff

Keep in mind also that the ECM maintains pulse code count on the IAC stepper motor to know where the valve position is and for various reasons can loose position knowledge of the valve. For example when power is lost to the ECM (like disconnecting the battery) the ECM drives the valve fully closed when the key switch is first turned on then opens fully to establish valve stroke position relative to stepper count then sets a nominal cranking position.

So, have you tried to completely remove the power to the engines and allow a reset of the IAC's? As another note turning the battery switches off will not completely remove power from the ECM's; only way is to fully disconnect the batteries.

Last edited:

CliffA

Well-Known Member

- Dec 29, 2009

- 4,712

- Boat Info

- 2001 Sea Ray 340DA

Name: 'Happy Place'

4.5kW West. Generator

Purchased Nov. 2014

Fresh Water Use

- Engines

- Twin Merc. 6.2L (MPI)

640 hp (Total)

Raw Water Cooled

V-Drive Transmissions

I don't think so; I believe the Mercury IAC's are PCM driven stepper motors and can only be positioned using the ECU. Maybe simple remove the IAC and look in it to see how crapped up it is and clean with a good aerosol carburetor cleaner. Might have to spray some in, let it set for a while, then flush out with more cleaner.

10-4......thanks.....

cliff

CliffA

Well-Known Member

- Dec 29, 2009

- 4,712

- Boat Info

- 2001 Sea Ray 340DA

Name: 'Happy Place'

4.5kW West. Generator

Purchased Nov. 2014

Fresh Water Use

- Engines

- Twin Merc. 6.2L (MPI)

640 hp (Total)

Raw Water Cooled

V-Drive Transmissions

since I cannot extend the pintle all the way out would you recommend using a light penetrating oil such a '3 in 1' oil instead of a heavy oil to lubricate the shaft after cleaning it with throttle body cleaner?.....I'm thinking this may help ensure the oil gets past any seal on the shaft so the entire shaft is lubricated.....

cliff

cliff

atrick

Active Member

- Mar 4, 2017

- 548

- Boat Info

- 1998 400 Searay Sedan Bridge

1995 Searay 290 Sundancer

1990 21 maxum

2001 24' FlotBot Pontoon Boat

- Engines

- Twin 3116 Cats

Twin 4.3 mercrusers

305 chevy with a alpha one drive

Yamaha 90 HP Outboard

I would think any kind of oil would attract dirt, maybe some kind of silicone and maybe use contact cleaner to clean it as its made more for electrical components than is carb cleaner.

CliffA

Well-Known Member

- Dec 29, 2009

- 4,712

- Boat Info

- 2001 Sea Ray 340DA

Name: 'Happy Place'

4.5kW West. Generator

Purchased Nov. 2014

Fresh Water Use

- Engines

- Twin Merc. 6.2L (MPI)

640 hp (Total)

Raw Water Cooled

V-Drive Transmissions

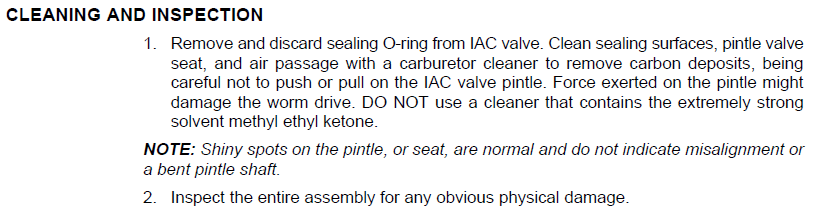

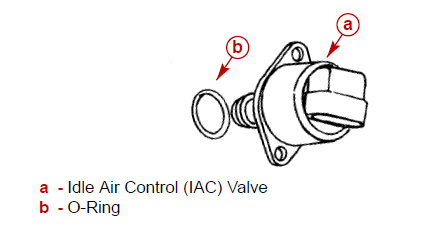

I looked at the Merc Service Manual and it has a write up for cleaning the IAC.....it does not mention using any oil probably for the reason atrick mentioned....

here is the IAC cleaning instructions from the service manual in case someone following this thread wants to clean their IAC valves:

cliff

here is the IAC cleaning instructions from the service manual in case someone following this thread wants to clean their IAC valves:

cliff

sdarc

Well-Known Member

Cliff, I've been following this. I hadn't put my .02 in as others have given you great advice. After re-reading the thread something jumps out at me from your first post. After going to the gas dock and leaving the engines running all that time the issue went away. That tells me the engines are now thoroughly warm. In cooler weather the coolant temps may reach operating temps but that doesn't mean the engines are fully warm. take a lot more to heat all that iron.

I had this happen to me on my first Sea Ray but it was carbed so I didn't think it to be the same. The more I read the thread and thought about it I think it is that the engines are not fully warmed up yet.

I would still clean the IAC's cause it can't hurt.

Good luck

I had this happen to me on my first Sea Ray but it was carbed so I didn't think it to be the same. The more I read the thread and thought about it I think it is that the engines are not fully warmed up yet.

I would still clean the IAC's cause it can't hurt.

Good luck

CliffA

Well-Known Member

- Dec 29, 2009

- 4,712

- Boat Info

- 2001 Sea Ray 340DA

Name: 'Happy Place'

4.5kW West. Generator

Purchased Nov. 2014

Fresh Water Use

- Engines

- Twin Merc. 6.2L (MPI)

640 hp (Total)

Raw Water Cooled

V-Drive Transmissions

Cliff, I've been following this. I hadn't put my .02 in as others have given you great advice. After re-reading the thread something jumps out at me from your first post. After going to the gas dock and leaving the engines running all that time the issue went away. That tells me the engines are now thoroughly warm. In cooler weather the coolant temps may reach operating temps but that doesn't mean the engines are fully warm. take a lot more to heat all that iron.

I had this happen to me on my first Sea Ray but it was carbed so I didn't think it to be the same. The more I read the thread and thought about it I think it is that the engines are not fully warmed up yet.

I would still clean the IAC's cause it can't hurt.

Good luck

thanks Steve.....the engines not being fully warmed up could also fit into the scenario of a sticking IAC valve.....if the IAC pintle has 'crud' built up on it the cold weather could make the sticking of the pintle worse by not allowing the pintle to slide in and out of the throttle body easily....as the engine fully warms up it is possible the 'crud' on the pintle is also warming up and allowing the pintle to slide in and out of the throttle body more easily.....

cliff

scoflaw

Well-Known Member

- Aug 10, 2011

- 6,395

- Boat Info

- 1999 Powerquest legend 260 sx 502 mag

2005 Baja 242 islander 496

- Engines

- 502 mpi Bravo 1

496 mag B1

Not sure I would assume warm crud is a lubricant. If in fact it is your IAC they usually develop their problem by not extending or retracting within themselves, not getting snagged up in the TB bore. How far they extend is measured in counts, and the scan tool will give you that number.

CliffA

Well-Known Member

- Dec 29, 2009

- 4,712

- Boat Info

- 2001 Sea Ray 340DA

Name: 'Happy Place'

4.5kW West. Generator

Purchased Nov. 2014

Fresh Water Use

- Engines

- Twin Merc. 6.2L (MPI)

640 hp (Total)

Raw Water Cooled

V-Drive Transmissions

Not sure I would assume warm crud is a lubricant. If in fact it is your IAC they usually develop their problem by not extending or retracting within themselves, not getting snagged up in the TB bore. How far they extend is measured in counts, and the scan tool will give you that number.

thanks....wasn't really referring to warm crud as a lubricant....more like it as being 'less restrictive' concerning the movement of the pintle.....if cleaning the IAC valves has no effect on the issue and the voltage test of the TPS looks OK i'll call in the mechanic for a scan of the engines...

cliff

CliffA

Well-Known Member

- Dec 29, 2009

- 4,712

- Boat Info

- 2001 Sea Ray 340DA

Name: 'Happy Place'

4.5kW West. Generator

Purchased Nov. 2014

Fresh Water Use

- Engines

- Twin Merc. 6.2L (MPI)

640 hp (Total)

Raw Water Cooled

V-Drive Transmissions

to close out this thread, between crappy weather and family obligations over the past several weeks I finally had some time to work on the engines.....I cleaned the throttle body, flame arrestor, and the IAC valves on both engines but that did not help.....since the TPS were original and have internal moving parts that can and do wear over time I decided to replace the TPS on both engines to establish a baseline for these important sensors....this cured the problems with the port engine but not the starboard engine.....I decided to also replace the IAC valve on the starboard engine and this cured the problems....

so the 'cure' for the surging and stalling was a combination of IAC valves and TPS.....after also installing two new serpentine belts due to some 'chirping' from both engines that increased belt tension would not stop we took the boat out this WE for about 3 hours and all went well.....

cliff

so the 'cure' for the surging and stalling was a combination of IAC valves and TPS.....after also installing two new serpentine belts due to some 'chirping' from both engines that increased belt tension would not stop we took the boat out this WE for about 3 hours and all went well.....

cliff

Last edited: