- Aug 25, 2008

- 1,819

- Boat Info

- 2006 320 V-Drives 6.2s, Bow Thruster, Generator, Raymarine C80, Radar, Fish Finder

- Engines

- 6.2 Horizons 320HP

My boat hasn't been running for almost a month. My port engine shut off unexpectedly 10 feet from the dock. I determined that I was not getting fuel, but didn't know why. I took it to the local marina for repairs. One week later they told me they found the problem, it was a bad relay. They charged me just over $300 for 2 hours labor and relay switch. I picked the boat up an took it home. (The marina is less than 1 mile away down the lagoon)

The next day I went for a ride and made it as far as the no wake buoy by my house and the engine shut down again. Total drive time was less than 10 minutes from when I picked the boat up from the marina. I limped back home and tied up for the night. The next morning I decided to go and purchase another relay and install it myself to see if burnt out again. I installed the new relay and the engine still wouldn't start. I decided to take it back to the marina again for repairs. I told them that I looked at the plug that the relay plugs into and it looked damaged. I explained that my eyesight wasn't that good, but I think there may be a problem with the plug. I was told by the service manager that he would ask the mechanic to look at it.

They didn't look at the boat until 4:00 the following Friday. They called me and told me that my relay was fine but my fuel pump was seized and I needed a new cool fuel 3 unit. The price would be $1500 with labor. I asked if they had the part in stock and they told me they had to order it and it would be in the following Tuesday.

Tuesday arrives and I get a phone call that the unit is back ordered and would not be in for another 2 weeks! I finally had enough I told him I was coming to pick the boat up and I would fix it myself. So I get the boat back and decide to test the power going to the fuel pump to see if it is getting power. I determine that I get 12 volts down at the fuel pump when I hit the power switch up at the dash. I decide to go with the marinas diagnosis of a seized pump I order a new Cool Fuel 3 unit.

When I removed the original unit, the water plastic inserts in the water hoses cracked, which was predicted in Frank Webster's write up about these poorly designed POS. I also found that the pump had been dripping sea water onto my motor mount which had a considerable amount of rust on it.

After removing the pump, I decide to take it apart to test the individual pumps and determine that they are both working. ARGH!! You can guess what happens next. I install the new Cool Fuel 3 and I right back where I started. Engine wont start, fuel pump not running. Up until this point I was reluctant to touch the other engine, but out of sheer frustration I decide to take the relay from the starboard engine and try in my port engine. I hear the pumps running and the engine starts! My luck doesn’t last long. I took the boat for a quick ride, returned and washed it and decided to go out again but it doesn’t start.

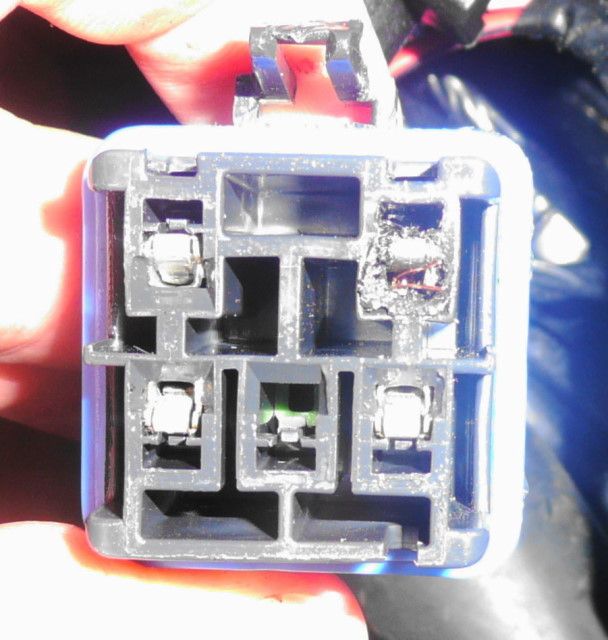

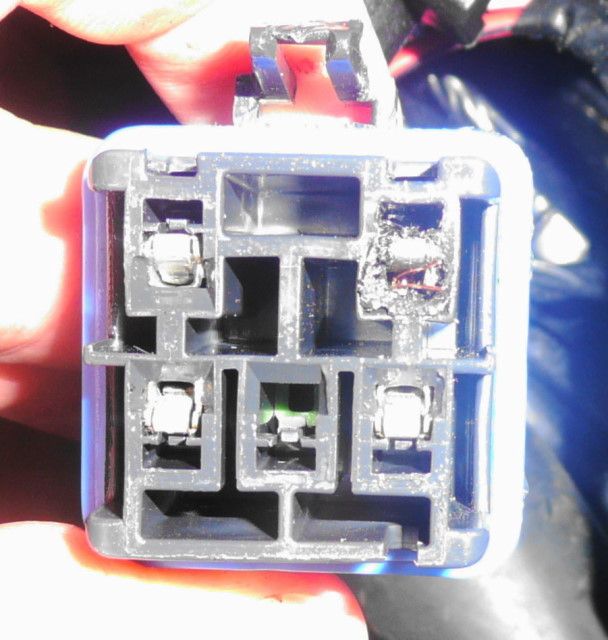

I took the following picture of the plug that the relays plugs into and blew it up. There is clearly damage to one of the legs and I am not getting good contact. I tried to put a few strands of copper wire in the plug to see if that helped make contact and it didn’t. (you can see there is still one strand in plug when I took the picture) I went on line to see if I can purchase the plug and found out that it is part of the engine wiring harness and is not sold separately. The wiring harness retails for $900.00.

Any suggestion on how to fix this? Is there a junk yard for Mercruiser engines where I can purchase a plug? This has not been a good boating season for me.

4 weeks in August, without my boat, $2200 out of pocket expense (I purchase 2 new Cool Fuel 3 units with the intention of replacing the other one as well), and my boat still isn’t running

The next day I went for a ride and made it as far as the no wake buoy by my house and the engine shut down again. Total drive time was less than 10 minutes from when I picked the boat up from the marina. I limped back home and tied up for the night. The next morning I decided to go and purchase another relay and install it myself to see if burnt out again. I installed the new relay and the engine still wouldn't start. I decided to take it back to the marina again for repairs. I told them that I looked at the plug that the relay plugs into and it looked damaged. I explained that my eyesight wasn't that good, but I think there may be a problem with the plug. I was told by the service manager that he would ask the mechanic to look at it.

They didn't look at the boat until 4:00 the following Friday. They called me and told me that my relay was fine but my fuel pump was seized and I needed a new cool fuel 3 unit. The price would be $1500 with labor. I asked if they had the part in stock and they told me they had to order it and it would be in the following Tuesday.

Tuesday arrives and I get a phone call that the unit is back ordered and would not be in for another 2 weeks! I finally had enough I told him I was coming to pick the boat up and I would fix it myself. So I get the boat back and decide to test the power going to the fuel pump to see if it is getting power. I determine that I get 12 volts down at the fuel pump when I hit the power switch up at the dash. I decide to go with the marinas diagnosis of a seized pump I order a new Cool Fuel 3 unit.

When I removed the original unit, the water plastic inserts in the water hoses cracked, which was predicted in Frank Webster's write up about these poorly designed POS. I also found that the pump had been dripping sea water onto my motor mount which had a considerable amount of rust on it.

After removing the pump, I decide to take it apart to test the individual pumps and determine that they are both working. ARGH!! You can guess what happens next. I install the new Cool Fuel 3 and I right back where I started. Engine wont start, fuel pump not running. Up until this point I was reluctant to touch the other engine, but out of sheer frustration I decide to take the relay from the starboard engine and try in my port engine. I hear the pumps running and the engine starts! My luck doesn’t last long. I took the boat for a quick ride, returned and washed it and decided to go out again but it doesn’t start.

I took the following picture of the plug that the relays plugs into and blew it up. There is clearly damage to one of the legs and I am not getting good contact. I tried to put a few strands of copper wire in the plug to see if that helped make contact and it didn’t. (you can see there is still one strand in plug when I took the picture) I went on line to see if I can purchase the plug and found out that it is part of the engine wiring harness and is not sold separately. The wiring harness retails for $900.00.

Any suggestion on how to fix this? Is there a junk yard for Mercruiser engines where I can purchase a plug? This has not been a good boating season for me.

4 weeks in August, without my boat, $2200 out of pocket expense (I purchase 2 new Cool Fuel 3 units with the intention of replacing the other one as well), and my boat still isn’t running