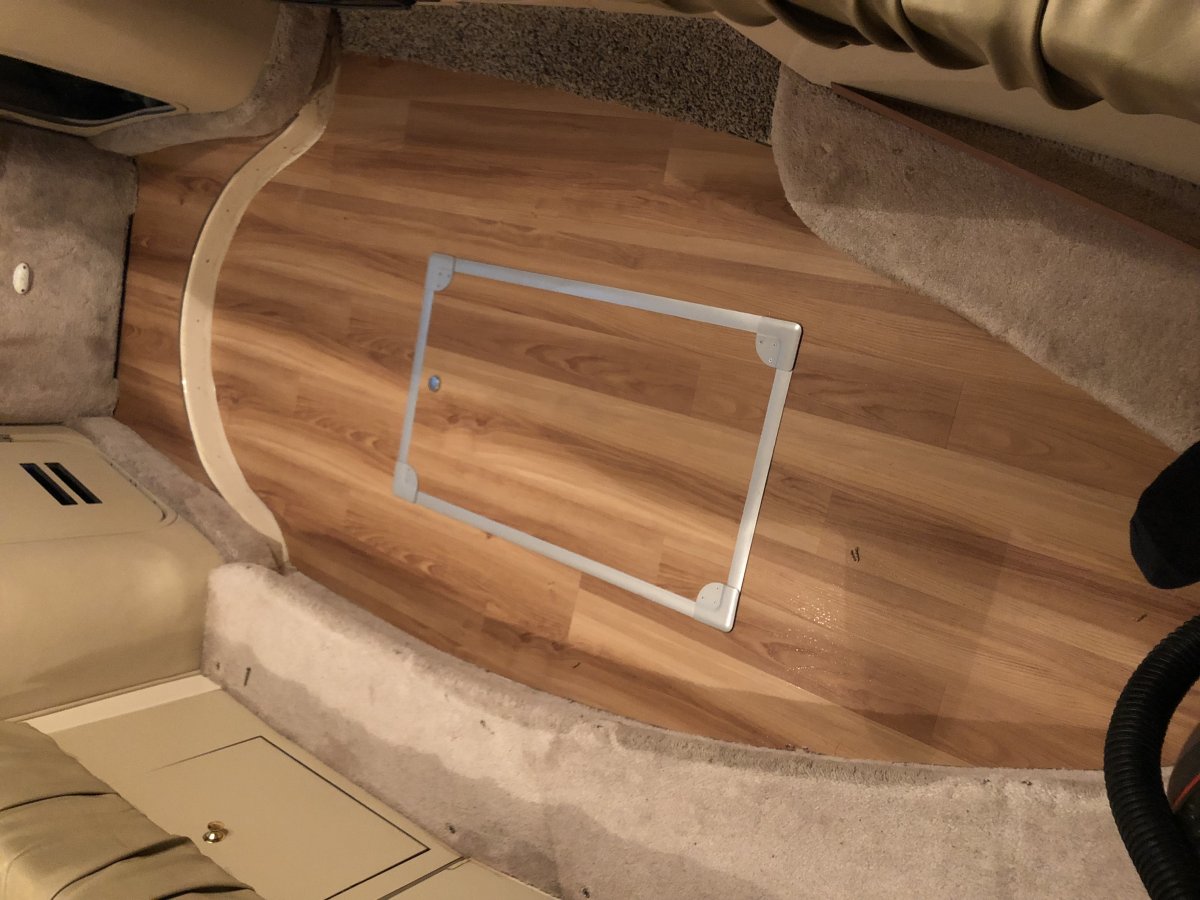

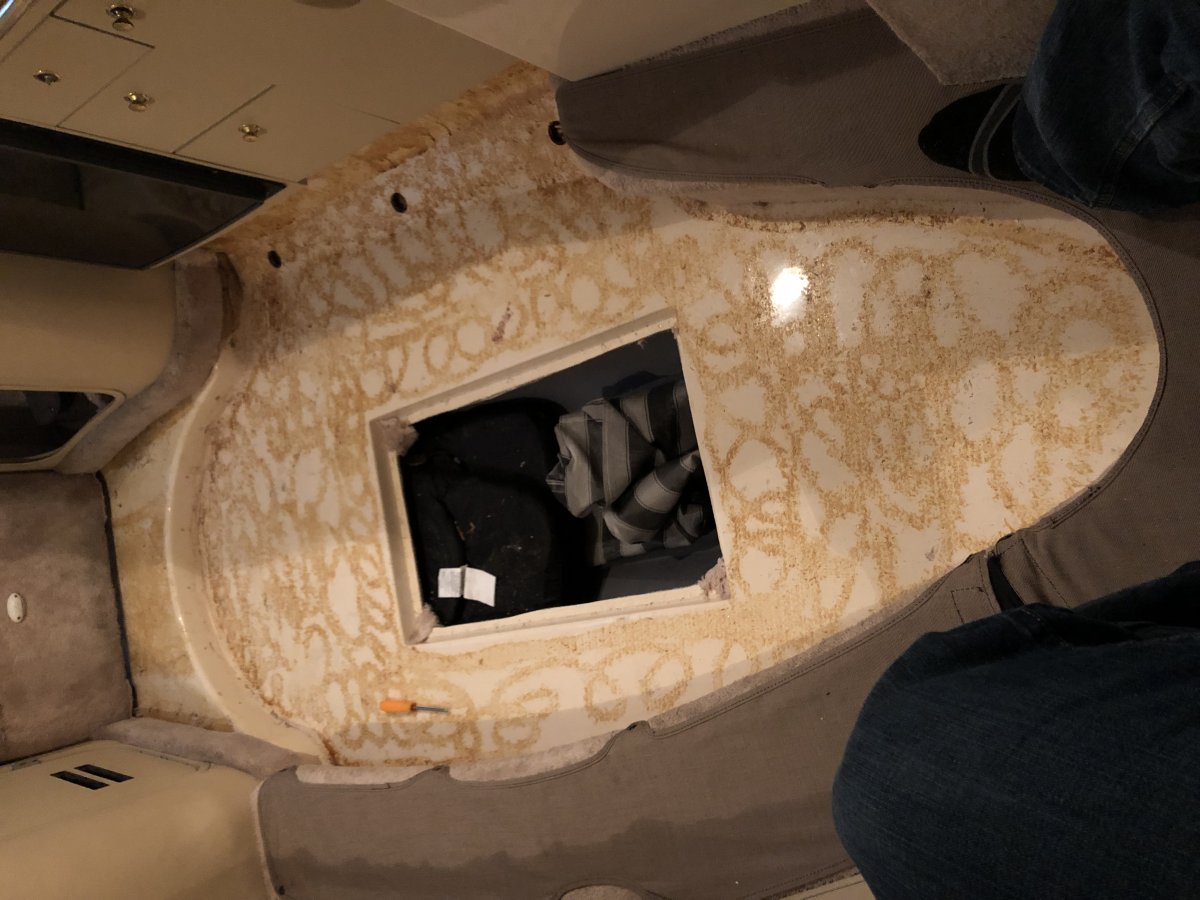

Thought a few might be interested in following along. I’m gojng to be putting vinyl “wood” flooring down in the cabin if our 290. Judging by the other threads over the years it would appear I got very lucky because it took 20 minutes to pull the carpet up. The sole is all gelcoated glass, so I’m just going to hit it with an orbital sander quick and it should clean right up. It is already pretty flat as is. Here are the first pics.

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature currently requires accessing the site using the built-in Safari browser.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

“Wood” floor in cabin - 98 290

- Thread starter Strecker25

- Start date

QT1

Active Member

- Oct 20, 2016

- 647

- Boat Info

- 1990 350 Sundancer, "Quality Time II".

- Engines

- 454 Mercruisers, performance parts modified by PO.

Are you planning on using the Allure flooring? I am in the mist of doing the floor of my boat shortly

Are you planning on using the Allure flooring? I am in the mist of doing the floor of my boat shortly

Sure am, originally grabbed the thinner stuff (with the adhesive strip) but I took it back for the higher end click lock. I’m probablg going to have to glue the first step down but the rest I should be able to let float. Post some pics of your install in here if you have them, I’d love to see it

Here’s the first template and fitting. It’s not pushed all the way under the step which is why you see a gap. I’m up in the air on the edge, the gelcoat is nice and it’s a gentle radius so I might cut smooth and just caulk the edge to blend into the gelcoat. I’m using some asphalt underlayment I had left over for templates. It works great, rigid but easy to cut.

BillK2632

Well-Known Member

That is going to really look nice!

frosh coach

Member

- Apr 20, 2011

- 237

- Boat Info

- 1997 300 DA,

1994 300 DA (SOLD)

1989 230 (SOLD)

- Engines

- Twin Mercruiser 350 FWC, 300 HP MPI V-drives

Look good. I'll be following as well.

CliffA

Well-Known Member

- Dec 29, 2009

- 4,712

- Boat Info

- 2001 Sea Ray 340DA

Name: 'Happy Place'

4.5kW West. Generator

Purchased Nov. 2014

Fresh Water Use

- Engines

- Twin Merc. 6.2L (MPI)

640 hp (Total)

Raw Water Cooled

V-Drive Transmissions

me too.....

cliff

cliff

Here is what should be the final cut on the step. I hope to rough template the rest of the floor today and then this weekend get it trimmed and start cutting the rest. For anyone looking at doing this,a multi tool is an absolute must. It’s so versatile on this type of work.

wyrman

Well-Known Member

- Jul 12, 2012

- 1,921

- Boat Info

- 2007 310 Sundancer

- Engines

- Twin 350's, V drives

2003 Fisher 17 aluminum

90hp Honda 4 stroke

What are you using where the horizontal meets the vertical?

I haven't totally decided yet. I'm going to use this for the hatches: https://jonnycorners.com/portfolio/the-corners/

So I might see if they can help design something for the front edge. If you check out the first post closely you'll see the vertical part is actually nicely gelocoated so I will leave that exposed, and then use some vinyl quarter round where the new floor meets it.

This stuff is interesting for the areas in need of molding. It says stainable and paintable

https://www.amazon.com/Flexible-Moulding-Quarter-Round-Straight/dp/B006R99T0U

So I might see if they can help design something for the front edge. If you check out the first post closely you'll see the vertical part is actually nicely gelocoated so I will leave that exposed, and then use some vinyl quarter round where the new floor meets it.

This stuff is interesting for the areas in need of molding. It says stainable and paintable

https://www.amazon.com/Flexible-Moulding-Quarter-Round-Straight/dp/B006R99T0U

Last edited:

Got the floor down. No glue needed so far, might let it float for the start of the season and see if it needs a tack in a few places. I think I’m going to just refresh the carpet under the slanted part beneath the galley, then use a T molding to transition. Same for the step, you can see a picture below but I actually like the look of the carpet as a riser, it just needs new carpet since it’s a little stained. The alternative is flexible molding and leaving he gelcoat exposed but the carpet fits the rest of the interior I think. Hatch and flexible quarter round will finish it up next week

Little more today. We are giving a different shade of carpet a go for under the galley and stair riser. I couldn’t find an exact match, but I also don’t need any glue to hold it in place so if we decide it looks dumb I can change it. Also finished the hatch, had to build it up with 5/8 plywood. I’ll put it on the boat tomorrow. The molding is from jonnycorners.com

QT1

Active Member

- Oct 20, 2016

- 647

- Boat Info

- 1990 350 Sundancer, "Quality Time II".

- Engines

- 454 Mercruisers, performance parts modified by PO.

Wont be able to start my wood floor project until well after my shoulder surgery next Friday.

ZZ13

Well-Known Member

Looks good. I put the exact product throughout my boat (their Clear Cherry product). It's held up great for two years it's been installed. And we really like the lighter shade contrasting with the dark cheery cabinets. Somewhere on the 40 Sedan Bridge forum are my pics. At $63 a box it's practically free in boat cost terms.

Little Ducky

Well-Known Member

- Jun 5, 2017

- 2,654

- Boat Info

- 1998 290 Sundancer

- Engines

- Twin EFI 5.0L w/Alphas

Kohler 4kW

Good job. That looks great.

Thanks. The molding on the hatch is metal. It’s a kit from jonnycorners.com and you cut the length to fit. I cut it with a multi tool but a chop saw works too. They have a bunch of colors, we liked silver best.

ZZ13

Well-Known Member

I used this exact stuff on my install. It takes stain great. I found a picture of it I had posted. The full install pics are a few pages back if you want to do any comparison.I haven't totally decided yet. I'm going to use this for the hatches: https://jonnycorners.com/portfolio/the-corners/

So I might see if they can help design something for the front edge. If you check out the first post closely you'll see the vertical part is actually nicely gelocoated so I will leave that exposed, and then use some vinyl quarter round where the new floor meets it.

This stuff is interesting for the areas in need of molding. It says stainable and paintable

https://www.amazon.com/Flexible-Moulding-Quarter-Round-Straight/dp/B006R99T0U

http://clubsearay.com/index.php?threads/40-sedan-bridge-forum.53961/page-79#post-887970

Nice! Thanks. I’ll go ahead and order that.I used this exact stuff on my install. It takes stain great. I found a picture of it I had posted. The full install pics are a few pages back if you want to do any comparison.

http://clubsearay.com/index.php?threads/40-sedan-bridge-forum.53961/page-79#post-887970

I realized I put the boards in wrong as you can see the lines don’t match up. I’ll either remove them by taking one side off the hatch and sliding it in the other way or just flip the hatch around so the pull handle is towards the bow.