- Jun 5, 2016

- 5,592

- Boat Info

- 410 Sundancer

2001

12" Axiom and 9" Axiom+ MFD

- Engines

- Cat 3126 V-Drives

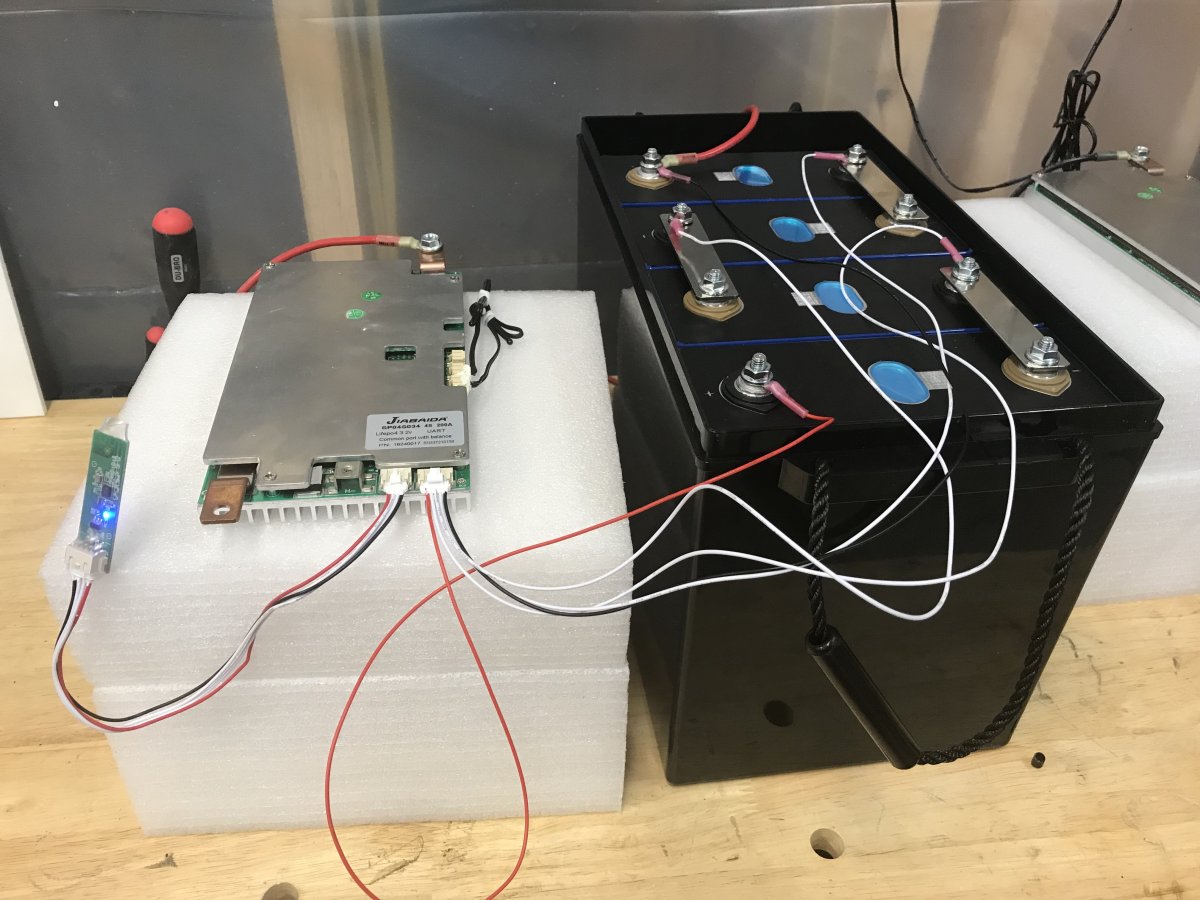

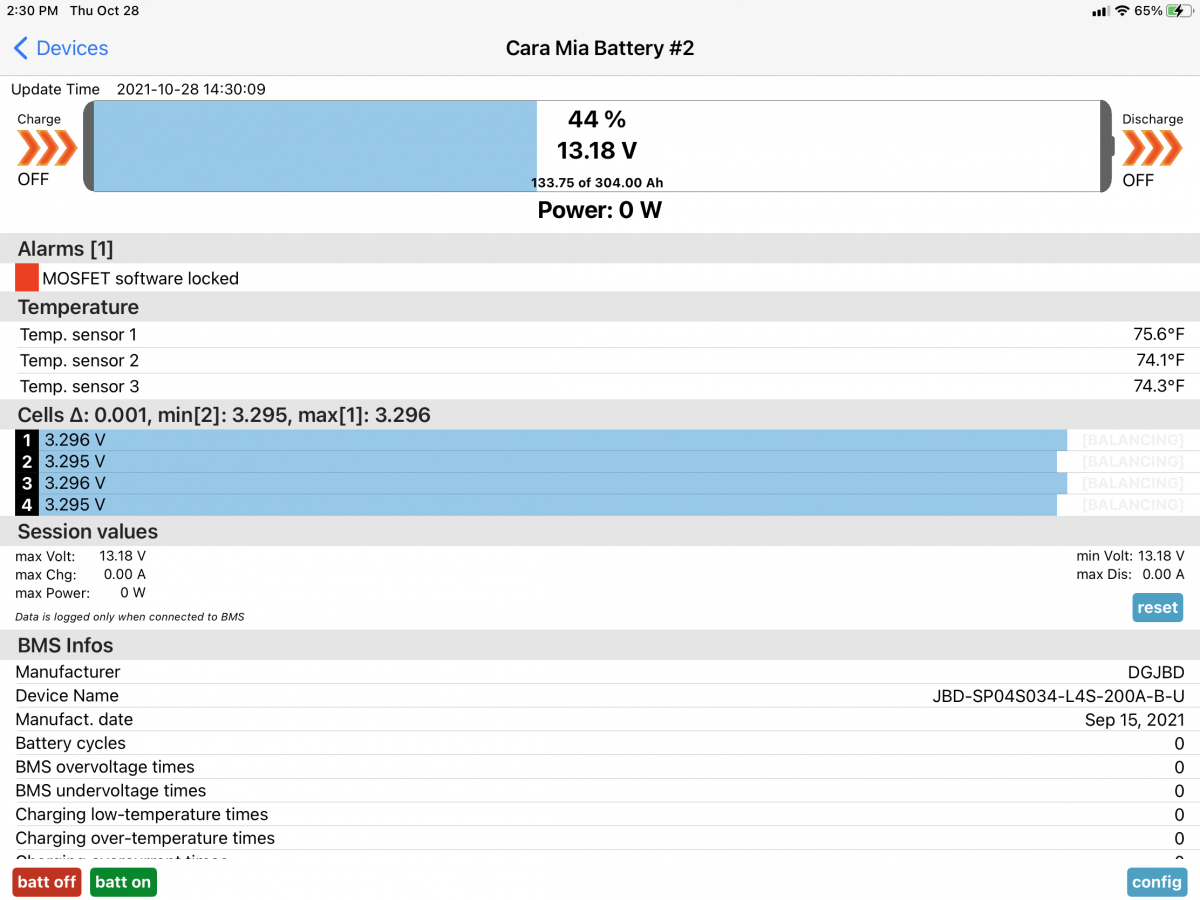

First order of business is to make sure the BMS are correct and workable as I ordered what I believe to be the OEM version of the Overkill Solar/Radio B BMS. These were JBD 4s 200A version that were about $100 each delivered.

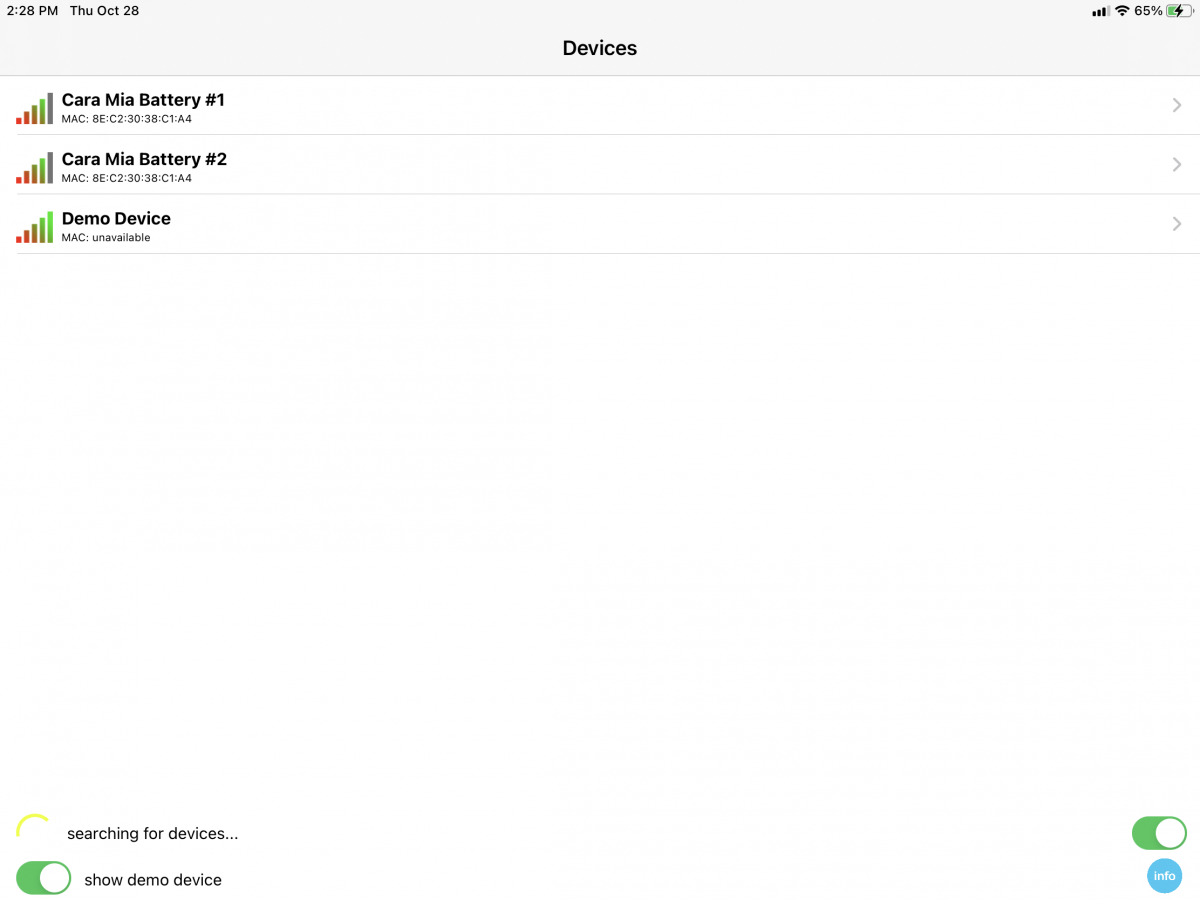

Connected up, and The Bluetooth connected right up to my iPad. I can’t get the Android version to work.

Next up, input all the correct parameters and download to the BMS, and then I need build a fixture to hold all 8 and top balance..

Connected up, and The Bluetooth connected right up to my iPad. I can’t get the Android version to work.

Next up, input all the correct parameters and download to the BMS, and then I need build a fixture to hold all 8 and top balance..